The world of supply chain experts loves a good turf war. When, ten years ago, I began to take an interest in the subject and to promote Demand Driven tactics...

In our education, delaying work is not good. If you’re in the supply chain business, you’re even more inclined to anticipate – you’re resolutely forward-looking. If you’re in the supply...

We meet companies who are investing hundreds of thousands or even millions of dollars in their own digitalization projects – systems designed to meet their specific supply chain processes. It’s...

Pull flow is not a new technique. In the industrial era, Kanban loops have been around since at least the middle of the 20th century. The principle has likely been...

In a production workshop, with a supplier, in transport, there are …brrr, it’s a bit scary… yes, yes… supply chain EMERGENCIES. In my career, I’ve seen all kinds: red, bright red,...

Cleaning up demand histories is a classic discipline for any forecaster in the supply chain. When generating a statistical forecast, you must first ensure that the historical data has been...

How do you manage job shop complexity? It involves manufacturing products, often complex ones, in a succession of manufacturing operations carried out on equipment specialized by technology. For example, we...

When you’re looking for IT systems to manage your supply chain, chances are you’ll be directed toward large, complex, and expensive systems. This trend dates back to the advent of...

In the ERPs of most factories, at any given time, there are many production orders with an end date in the past. A production order in the past means: “We...

The graph below shows the production orders created for a line of strategic finished products in an aeronautics plant. These are production orders, not planned orders. Each bar represents one...

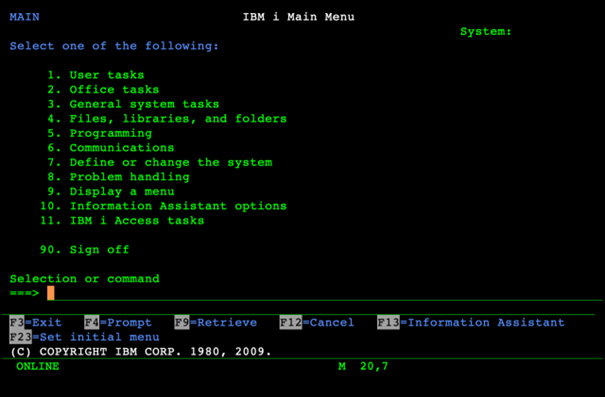

In the early 90s, I was in charge of IT at a Philips industrial site and had the good fortune of being in charge of our IBM 38 replacement with...

One of the strengths of the DDMRP methodology is its ability to efficiently manage dynamic stock buffers. A DDMRP buffer with three zones (red/yellow/green) describes a replenishment loop that continuously...

We were recently approached to tender by a company looking for a forecasting and procurement solution. The tender included all the buzzwords of the moment: AI, big data, and a...

Since the introduction of computer-based material planning solutions, planners and supplier chain managers have been scratching their heads trying to determine how to properly size inventory buffers and safety stock...

When the world becomes more complex, a little nuance doesn’t hurt… A binary approach doesn’t usually solve problems. This adage also applies to the planning of our supply chains. Our...