Real-time buffer optimization on autopilot

Don't waste months adjusting your inventory. Intuiflow helps you size the right protections for real demand variability in minutes. Automatically simulate replenishment tactics based on historical data and projections. This visibility allows your teams to confidently determine the required inventory levels.

Real-time buffer optimization on autopilot

Stop waiting weeks for consensus. Intuiflow helps you generate, compare, and stress-test demand projections in minutes. Track forecast accuracy down to the SKU, course-correct early, and unify your team around a single, reliable plan.

Outdated rules can’t keep inventory aligned to real demand

Manual inventory tuning

Outdated rules, constant rework

Set-and-forget safety stocks and weekly parameter reviews waste time and miss demand shifts.

One-size-fits-none policies

Global settings lead to overstock in one region and shortages in another.

Change feels risky

Limited visibility into impact makes planners hesitant to adjust.

With Intuiflow Auto Pilot

Dynamic buffers that self-adjust

Inventory levels adapt daily based on real consumption. No manual tuning required.

Tailored by site and SKU

Buffers align to local demand patterns and customer behavior at every location.

De-risk inventory changes with simulation

Run what-if scenarios on buffer settings to predict outcomes with precision.

Stop tuning inventory by hand

Book a demo and watch Auto Pilot eliminate manual rework.

INTUIFLOW

Let the system fine-tune what manual rules never could

- Data Exceptions

- Location Settings

- Simulations

-

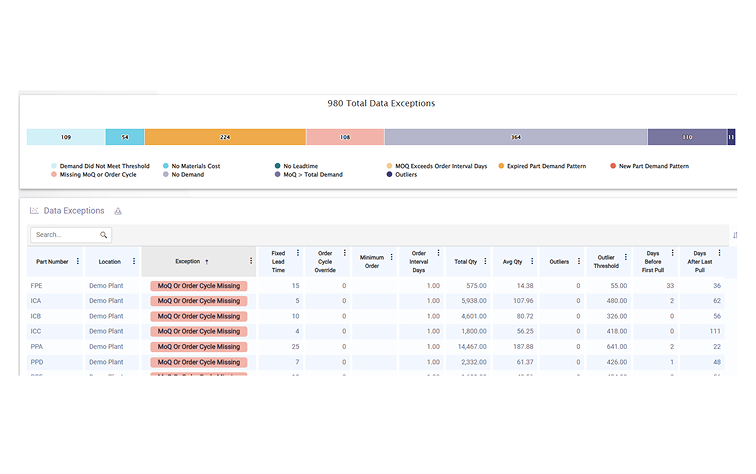

DATA EXCEPTIONS

Act on what matters, not what’s noisy

Auto Pilot monitors live demand and inventory behavior to surface only what’s worth attention. It flags anomalies like sudden demand spikes or creeping stockouts and sends prioritized alerts tied to real demand and performance risk.

-

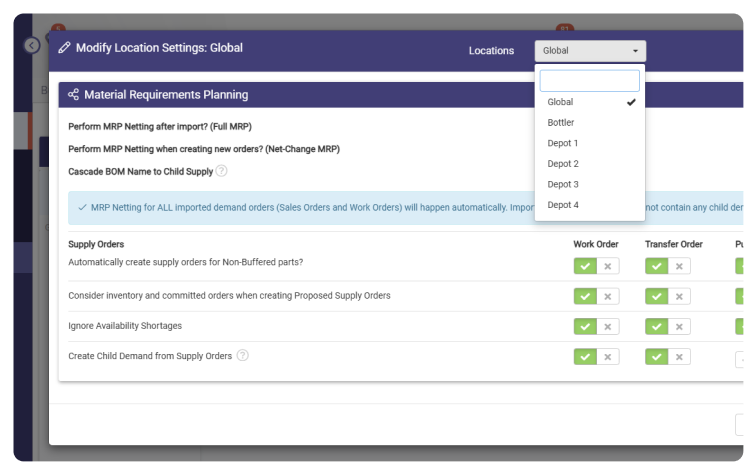

LOCATION SETTINGS

Fine-tune inventory to every market you serve

Auto Pilot adjusts buffer policies by site, customer type, or regional pattern automatically. Whether you're dealing with high-turn SKUs in a metro hub or low-volume items in a rural DC, inventory adapts to hyper-localized needs in real time.

-

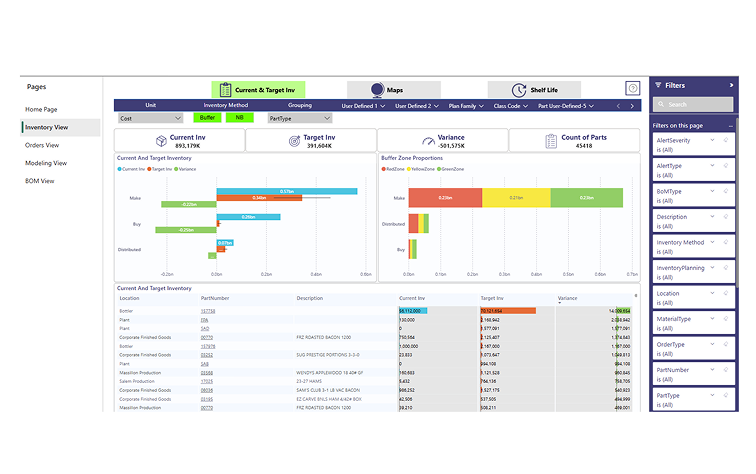

SIMULATIONS

Simulate inventory changes before they hit your supply chain

Preview the impact of buffer adjustments across SKUs, locations, and service level targets. Test what happens to availability, inventory levels, and flow before applying a single change to the live plan.

Partnering with Intuiflow has given me firsthand insight into how integrated manufacturing and demand-driven planning can work together to elevate supply chain performance and responsiveness.

Brent Mosley

Director of Supply Chain at Flogistix

Intuiflow integrates with all ERPs

Get out of spreadsheets. Let Auto Pilot optimize your inventory in real time

Intuiflow’s Auto Pilot FAQs

How does Auto Pilot actually adjust buffers in real time?

Auto Pilot continuously evaluates real consumption patterns against service level targets. It fine-tunes buffer levels daily, SKU by SKU, using demand-driven logic, not static rules, so inventory always reflects what’s really needed across your network.

Will I lose control if buffer settings are automated?

Not at all. Auto Pilot gives you full visibility into every adjustment, with exception-based alerts and built-in simulations. You see what’s changing, why it’s changing, and what the impact will be, before it happens.

Can I customize settings for different products or locations?

Yes. Auto Pilot supports hyper-local inventory strategies. You can tailor buffer policies by site, customer type, or product category, so each location runs lean but protected.

What if demand changes suddenly?

Auto Pilot is built to respond to variability. It surfaces demand spikes, supply delays, and anomalies through exception alerts, helping you act quickly without scanning reports or hunting through spreadsheets.

How are simulation features used in Auto Pilot?

Simulations let you test policy changes before deploying them. Whether adjusting service levels or fine-tuning a buffer, you can preview the impact across your network, minimizing risk while improving decision quality.

How long does it take to see results with Auto Pilot?

Most teams start seeing measurable improvements in inventory balance, service levels, and planner workload within a few weeks. Because Auto Pilot works with your live data, it delivers value fast without long implementations or complex integrations.