Build schedules that withstand disruption

Replace infinite-capacity assumptions with dynamic scheduling based on real demand and real constraints. Intuiflow helps you prioritize work orders, pace resources, and deliver on time, even when the market shifts.

Build schedules that withstand disruption

Replace infinite-capacity assumptions with dynamic scheduling based on real demand and real constraints. Intuiflow helps you prioritize work orders, pace resources, and deliver on time, even when the market shifts.

Fixed schedules can’t handle real-world variability

Legacy scheduling

Misses due dates and erodes trust

Schedules collapse under real-world constraints and production slips.

Wastes time reacting to noise

Planners waste hours reshuffling schedules every time there’s a change.

Planning and execution are out of sync

The shop floor works off stale schedules or tribal knowledge.

Intuiflow scheduling & execution

Match production to real-world limits

Align production with what your lines can actually deliver and meet due dates with confidence.

Absorb disruptions before they derail flow

Strategic control points stabilize flow, so one delay doesn’t throw off your entire week.

Keep execution synced in real time

Visual scheduling boards and smart alerts help every team focus on what drives flow.

Stop relying on static schedules that fall apart

Book a demo to see how Intuiflow keeps execution on track even when plans change.

INTUIFLOW

Everything you need to prioritize, schedule, and deliver with confidence

- Finite Capacity Scheduling

- Resource Modeling

- Shop Floor Execution

- Promise Dates

-

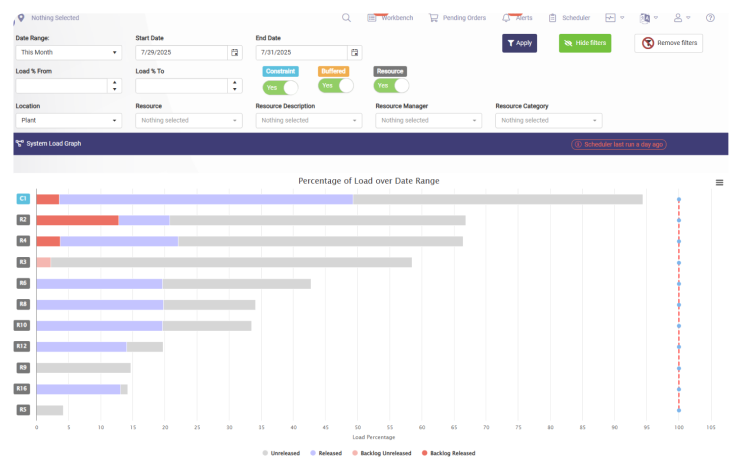

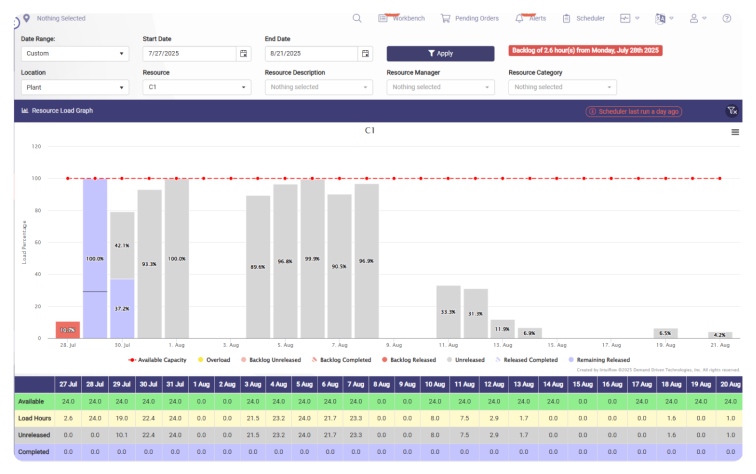

FINITE CAPACITY SCHEDULING

Build stable schedules that your team can actually run

Planning based on infinite capacity falls apart in the real world. Intuiflow’s constraint-based scheduling engine accounts for every bottleneck—people, machines, shifts—and gives you visual load graphs to see where adjustments are needed.

-

RESOURCE MODELING

Simulate, validate, and move forward with confidence

Whether you're testing a new shift schedule, adding demand, or working through a material shortage, Intuiflow shows you the impact across resources and timelines before you commit to anything.

-

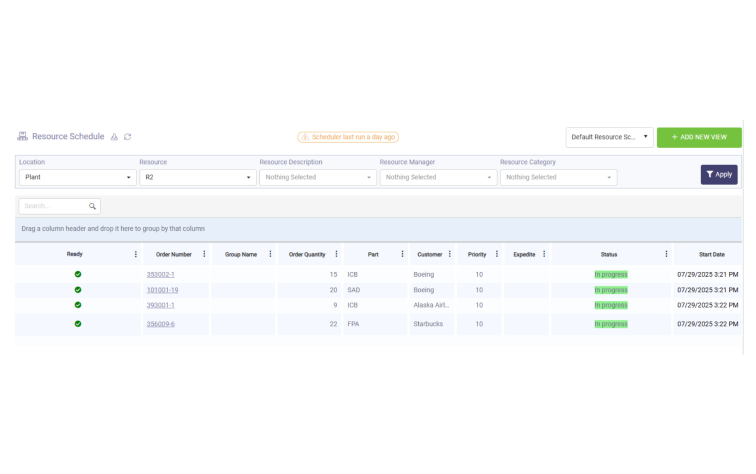

SHOP FLOOR EXECUTION

Get eyes on every order without manual updates

Intuiflow keeps your team aligned with real-time visibility into work order progress. Simple scheduling boards and streamlined input tools help your operators report fast, stay focused, and act on what drives flow.

-

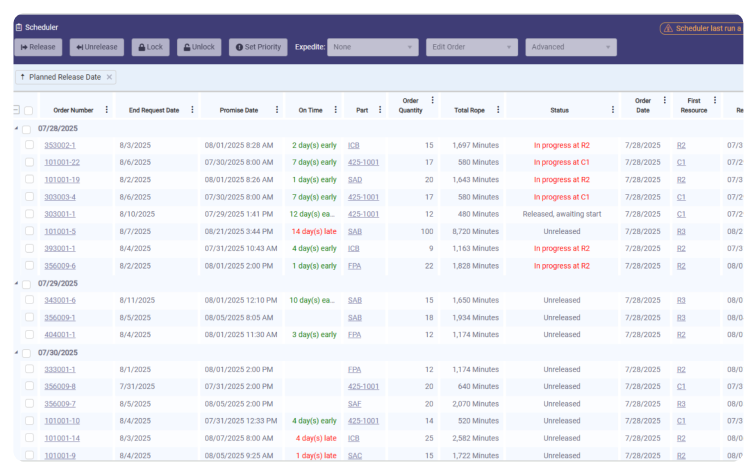

PROMISE DATES

Make delivery commitments you can keep

Give sales and customers promise dates that are grounded in actual capacity and materials, not spreadsheets or lead time rules. Intuiflow uses your real system constraints to calculate what’s truly possible.

Partnering with Intuiflow has given me firsthand insight into how integrated manufacturing and demand-driven planning can work together to elevate supply chain performance and responsiveness.

Brent Mosley

Director of Supply Chain at Flogistix

Intuiflow integrates with all ERPs

Ready to stop reacting and start executing with confidence?

Intuiflow’s scheduling & execution FAQ

What is demand-driven scheduling?

Demand-driven scheduling is a planning approach that uses real-time market signals and actual capacity constraints to create executable production schedules. Instead of relying on fixed forecasts or assuming infinite capacity, it adjusts dynamically to keep operations flowing, even when conditions change. It means you schedule only what’s needed, when it’s needed, based on real customer demand and real resource availability.

How does Intuiflow help improve production schedule reliability?

Intuiflow builds level-loaded schedules based on what your lines can actually produce, not what you hope they can. By prioritizing based on real demand and buffering variability with control points, teams hit due dates more consistently and reduce the chaos of daily rescheduling.

Why do traditional scheduling systems break under change?

Legacy scheduling assumes a perfect world; predictable demand, unlimited capacity, and stable priorities. But in the real world, change is constant. Traditional systems collapse when disruptions hit, while Intuiflow adapts in real time to keep execution on track.

Can Intuiflow handle finite capacity scheduling?

Yes. Intuiflow includes a constraint-based scheduling engine that evaluates load against actual capacity. It highlights bottlenecks and shows exactly where adjustments are needed, so you don’t overpromise or overload critical resources.

How does Intuiflow align planning with shop floor execution?

Intuiflow replaces tribal knowledge and disconnected spreadsheets with live scheduling boards and smart alerts. Teams know what matters most, track orders in real time, and stay aligned with customer priorities across every shift.

Does Intuiflow integrate with my ERP or MRP system?

Yes. Intuiflow integrates seamlessly with most ERP and MRP systems. It pulls your existing data and layers on real-time scheduling logic, so your team gets better decisions without replacing your core systems.

What’s the impact of Intuiflow on operational performance?

Companies using Intuiflow reduce missed due dates, lower rescheduling effort, and respond faster to changes in demand or availability. The result: smoother execution, higher throughput, and fewer surprises on the shop floor.

Who is Intuiflow’s Scheduling & Execution module built for?

It’s built for manufacturers and operations leaders who face constant change, especially in industries like automotive, industrials, aerospace, and electronics. If you’re tired of firefighting and need stable, adaptive scheduling, this module is for you.