More than once in my career as a supply chain manager, I have been faced with this demand: "Just put X days' worth of stock in." This demand could come from the sales director or even the CEO.

Supply chain managers, if you receive an order like this, you need to take a deep breath, calm down, and switch into teaching mode...

One month's worth of stock, 10 days' worth of stock, 30 days' worth of stock—as a target—means nothing.

Let's take a random example from one of our customers. A fairly stable item, sold frequently—this item has been in demand for 148 days over the past year—it sells on average every 2 business days, so it's really a big seller for this company.

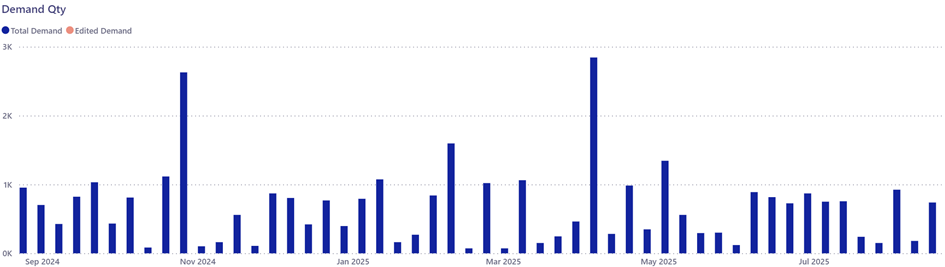

Here is the weekly demand history for this item. It fluctuates between 70 and 2,900.

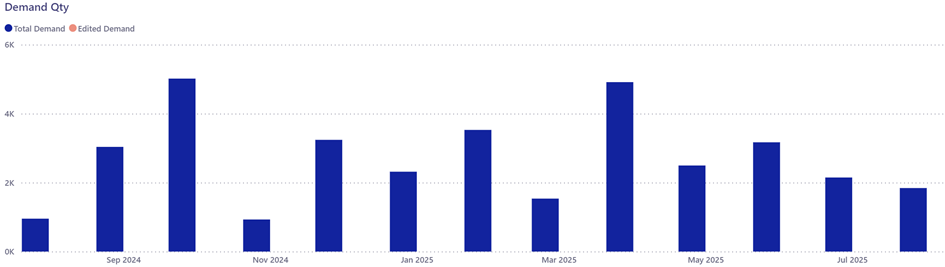

Per month, it fluctuates between 900 and 5,000.

OK, let's try to maintain a month's worth of stock – but does that mean we should aim for 900 or 5,000?

This item is a big seller.

For more erratic items, the disparities will be even greater.

The next time your sales counterpart says, "Put 30 days' worth of stock," don't hesitate to reply, "Yes, of course, let's look at it together to see how much that is"...

After the fact, when you analyze historical performance with the help of Finance, you have indeed found that your inventory represented a certain number of days of COGS. A number of days of inventory on hand to measure your performance after the fact—or a measure of inventory turnover—makes sense to verify that you are making progress and fosters continuous improvement.

But as an inventory target, it makes no sense, because it simply ignores the components that determine inventory size:

- Variability in demand and supply,

- Batch sizes, minimum orders,

- Lead times,

- Capacity constraints that lead to stockpiling or destocking

- ...

To achieve one month's stock after the fact, with excellent service, some of your items may only have one week's stock because their variability is low, their lead time is short, their batch size is small, and you have plenty of capacity—while others may need more than three months' stock...

Curiously, this type of undifferentiated injunction remains very common in industry, including in large companies. For example, I have personally experienced this in large pharmaceutical groups—and it went hand in hand with high levels of stockouts...

If you want to size your inventory with full knowledge of the facts and have the arguments to explain this sizing to your stakeholders, please do not hesitate to consult us. Intuiflow allows you to size your inventory based on historical simulations, validated against your forecast scenarios, enabling you to understand at a glance the reasons behind this level of investment, because it is indeed about secure the right investment to secure your flows.