The events of the last two years have tested companies’ strength. Digitalization, the effects of the pandemic, and the reversal of market trends are rapidly transforming economic stability. The realities of modern business do not leave a chance for those who are slow to respond to the changes that are taking place. Prolonged reflection on the way out of a difficult situation makes a carefully prepared plan quickly become irrelevant, as the situation has become different.

Special value in such conditions is the opportunity not to develop your own solution to each problem, but to acquire and apply a ready-made proven tool, to take advantage of market leaders’ experience. Let’s consider the Fast Pack case study. They implemented the inventory management system, based on the DDMRP methodology.

Fast Pack is the largest fasteners supplier in Ukraine, DIY sector. Since 2007, the company has successfully cooperated with the Ukrainian leaders of the DIY retail – Epicentrk, Novaya Liniya, Leroy Merlin, exclusive deliveries of hardware products to shops of German brands Praktiker and OBI.

Fast Pack currently supports 83 partner stores with 15,000 pallets on 5,000 m2 of storage space and over 10 million deliveries during 2020.

The company has 12 000 SKUs in 12 product categories. Goods come from 10 countries in different parts of the world, every SKU has its own lead time.

With such scale and intensity of logistic processes the search for solutions for inventory management has become especially important.

Fast Pack is a business with a high level of automation and a highly motivated team. In the process of continuous improvement, the company sought to optimize its inventory management with the following objectives:

- Minimization of possible mistakes in procurement and supply planning, and reduction of the human factor role. Supply planning was in Excel, time-consuming, and not accurate.

- Ensure that the necessary range is always available to meet incoming demand.

- Increase of service level. Having achieved good performance in this direction, the company set itself even higher goals, to remain the best supplier for the nationwide retailers

- All supply planning and inventory management processes standardization and automation.

- Basic logistic conditions for each SKU parameterization. It was necessary to calculate the minimum batch volumes, order multiple quantities to the supplier or manufacture, products lead times, and the order frequency.

- inventory reduction, lead time for clients decreased, assurance of uninterrupted supply.

- Improved availability and processing of data on the movement of goods. Management and analysts needed to reflect the current state of inventories in real time.

- Building rational and low-risk supply chains, which is an important competitive advantage for such companies.

- Responding to the challenges of the pandemic – constraints, failures in production and logistics, volatility in demand.

Roads we choose

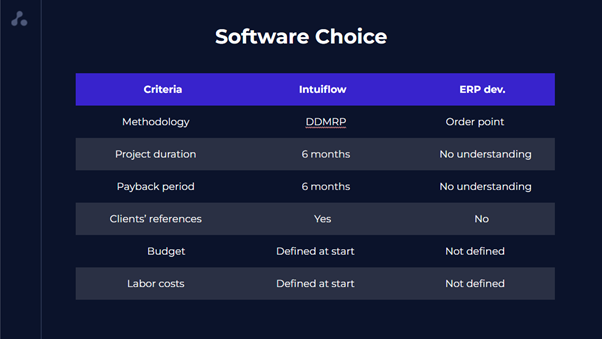

There are several ways to automate inventory management. For example, at your own risk, to develop new software or by modifying programs the company already uses or buy a finished software product with future support. Fast Pack had to make this choice between different ways to optimize inventory management. Top management considered the option to develop the ERP module. But the potential weaknesses of such a solution were detected:

- The need to create the methodology and algorithms for the program.

- Inability to reliably assess the main parameters of the project – labor costs, total budget, development time and ROI.

- Lack of quality assurance of software, its usability.

- Significant employees’ involvement in the implementation of IT-product.

Because of uncertainties and risks of self-development, it was advantageous to acquire the automated inventory management system. The ABM Cloud offer was convincing due to the successful implementation of the Intuiflow solution and DDMRP methodology in similar companies. Fast Pack representatives were able to get feedback from ABM Cloud clients, hear first-hand opinions and recommendations from users.

The inventory management solution was based on the following advantages:

- Satisfying implementation terms (6 months) and cost recovery period (6 months)

- SaaS model – no need to buy extra equipment

- The effectiveness of the methodology on which the software is based. DDMRP combines ideas from ToC, Lean, Six Sigma, MRP, DRP, and innovative developments.

- The ability to manage the entire supply chain, from the purchase of the goods to the stock management in the distribution.

- Compliance of the program functionality with inventory management objectives. The software optimizes stock levels, responds to demand growth, calculates, and maintains needed inventory quantities at key points in the supply chain.

- The implementation process carried out in stages, taking into account the peculiarities of the client’s business process, has been worked out and verified

- A qualitatively new level of data usability for managers.

- Training of Fast Pack personnel and after the introduction of the program

- Post-implementation technical and advisory support on an ongoing basis.

Implementation process: Step by step

The Fast Pack Inventory Management Optimization project included implementing the Intuiflow system to manage all active buffered and backordered nomenclature. It’s over 10,000 SKUs with lead times ranging from 3 to 200 days. The project was implemented in 3 stages. At each stage the project team was trained. At the initial stage, managers and specialists of sales, procurement, and warehouse logistics departments passed a two-day training in the DDMRP methodology and tested their knowledge. Fast Pack employees were convinced that the proposed concept has a lot of similarities with their own approaches. At the same time DDMRP presents more complete and systemic solutions in inventory management.

Since the implementation success largely depends on the data preparation quality, the first stage was to prepare data for use in an automated inventory management system and create and deploy the Intuiflow information base.

The Company’s work processes survey was carried out. This information was analyzed to understand what data already exists in the client’s ERP (1C), and what data needs to be updated or added.

Two problems were identified during the first stage – lack of purchase orders’ closure process formalization and accounting for work in progress. To eliminate them, Fast Pack IT specialists implemented and set up file exchange between 1C and Intuiflow.

It should be noted that the project team paid sufficient attention to such an important implementation element as the integration between the SaaS solution and ERP based on the 1C. Now, daily automatic data exchange between Intuiflow and ERP 1C has been established.

The project team standardized the parameters of each SKU: lead time, order cycle, minimum order quantity, multiple order quantity.

The SKUs were grouped by region from which they ship and their respective lead times:

- Ukraine (the shortest lead time)

- Europe (average lead time)

- Asia (longest lead time)

By systematizing and parameterizing SKUs, Fast Pack team was able to apply in Intuiflow a single, simple way to calculate reorder quantity and a clear priority for orders’ scheduling and execution.

In the second stage, the inventory management system was launched. As part of this stage, two user trainings were held for each program section and testing.

Then, errors in the data were corrected, the receiving and processing orders process were modeled, and buffers were calculated.

Consultants accompanied the managers’ work with the first orders received from Intuiflow. Among the achieved goals of the second stage is the formation of employees’ confidence in the program, and the development of the habit to start their working day in Intuiflow.

Pandemic test drive

In this second stage, the first positive results from the implementation appeared. This stage of the project took place at the beginning of 2021, a difficult period when the lockdown made it necessary to adjust plans literally on the run.

It can be said that the complete SaaS Intuiflow passed the test of the “perfect storm”. The closure of most retail outlets collapsed demand. The decrease in the number of orders has put employees in warehouses and packaging at risk, since their salary depends on the workload.

However, quarantine restrictions were not introduced forever, which means that it was necessary to maintain both qualified warehouse staff and the ability to accumulate goods to meet pent-up demand at the time when restrictions will be canceled, and retail will work.

To respond to such situations, the Intuiflow program includes CDAF. It’s a buffer adjustment factor, which was applied by the project team. Using this function allows you to evenly, for all positions, increase the buffer red zone by the number of sales days. Thus, the order to the manufacturer for the release and supply of SKUs arrives earlier than with normal system settings. In fact, at a certain moment, the production of those reserves is launched, due to which, after the restrictions are lifted, the accumulated pent-up demand will be satisfied, which exceeds the producers’ capabilities. At the same time, thanks to the methodology for determining the optimal cycle, the project team can recalculate the volumes of batches and order cycles, thereby regulating the number of changeovers, the workload of personnel and equipment of Fast Pack counterparty manufacturers.

Thus, the Intuiflow functionality allowed the company to respond flexibly to demand volatility, retain warehouse and packaging staff, and prepare for increased customer activity after the lifting of quarantine restrictions.

System parameter optimization

The task of the final stage of implementation was to prepare the company’s employees for the independent use of the DDMRP methodology and the Intuiflow in their daily work.

Personnel was trained to work with analytics and cloud solution settings using the Demand Driven Planner ™ training program. In addition to the operational level, the project participants focused on the supply chain model, which also includes tactical and strategic management levels.

Also at the third stage, the program parameters were adjusted, optimal production and supply cycles were calculated, and Fast Pack received recommendations on how to improve inventory turnover. The automated inventory management system has covered all ranges of Fast Pack products. Work with alerts, reporting and analytics has started.

If the customer’s staff studied the main capabilities of the cloud solution at the previous project implementation stage, then the third stage was devoted to finer parameters settings, more complete software functionality usage.

Above, we have already considered the use of one of the mechanisms incorporated in the Intuiflow logic to respond to significant and unforeseen fluctuations in demand. Similar functions are provided for considering predicted events and trends.

During the project, Fast Pack representatives experienced firsthand the effectiveness of applying buffer adjustments, as well as seasonality factors and unit conversion for inventory management.

Part of the assortment is characterized by seasonality. Accordingly, it is necessary to place orders for such commodity items in advance. Intuiflow uses seasonal factors (PAF) to dynamically adjust the buffer level to anticipated demand. If you receive information about upcoming scheduled events, such as notifications from suppliers about price increases or a scheduled maintenance stop, it is possible to create an additional stock of this manufacturer’s products. The already familiar CDAF adjustment factor allows you to increase the red or yellow zones automatically by adding a certain number of additional days of sales or storage units to them.

It should be noted the convenience of using a cloud system aimed at solving the daily trade and logistics specialists’ problems. For example, often operational accounting of goods is in pieces, packages, sets, etc. But the order to the supplier is made in units of transportation. The unit conversion factor present in the functionality helps to save staff time.

Implementation project completed, improvement process ongoing,

the implementation project was completed, as planned, in six months. The duration of each stage was two months.

Summing up the first results of the DDMRP implementation methodology, we can already say that the following results have been achieved:

- The ordering process is fully automated for production and procurement as well.

- During the period of using the system, the share of SKUs with overstocks and shortages decreased by 2 times the total number of positions.

- The service level has increased to 98%. The pre-project service level (percentage of on time in full orders) was already quite high, and it is well known from practice how hard it is for each “additional” (after 90%) percentage point of growth in this indicator. Nevertheless, the service level was improved and, most importantly, while reducing inventory.

- The overall stock level decreased by 20%, which means that the cost of storing goods was reduced, and the structure of the company’s working capital improved. Stocks of most of the items are maintained at the optimal level.

The company managed to achieve key results despite the fact that during the pandemic the suppliers’ service level decreased, at the same time, lead time lengthened by 30%, and demand volatility increased.

- The company managed to overcome the phenomenon of bimodal distribution, which is typical for many enterprises. It means that a lot of SKUs are out of stock. On the other hand, there are a lot of SKUs in overstock. An extremely small part of the SKU is at the optimal level.

- A flexible and timely response to fluctuations in actual demand was ensured through system usage and its functionality (dynamic buffers adjustment, correction factors, etc.).

- Reduced the probability of errors due to the so-called «human factor». Most of the decisions and calculations are performed automatically, according to system algorithms.

- Staff time has been used more rationally. The automated system ensures routine repetitive operations, allowing managers to focus on solving creative tasks.

The success of the project was largely determined by the fact that the Fast Pack team was open to new ideas and business processes revisions. The company’s employees have accepted and successfully applied the innovative DDMRP approach to managing material and information flows. Procurement Transparency and goods movement management processes simplify performance analysis at all stages of supply.

During its usage Intuiflow has demonstrated the ability to self-configure and has proven to be a reliable management tool. Thanks to it Fast Pack managed to get through the period of pandemic market turbulence without significant losses. Using the metrics generated by the system, the company shares the positive effect of DDMRP with its suppliers and customers. Thus, the demand driven inventory management approach optimizes the entire supply chain – from manufacturers, whose products are sold by Fast Pack, to the retail shelf.