Replenishment+

« Replenishment+ nous a permis de tirer parti de délais courts sur le marché et de créer un énorme avantage commercial, triplant notre bénéfice d’exploitation. »

~Bruce Janowsky , CEO - Jamestown Container Companies

Solution Supply Chain Pilotée Par La Demande

Alignez l'offre sur la demande réelle

Replenishment+ améliore considérablement la gestion de vos ressources en passant d’une planification basée sur les prévisions à une planification basée sur les commandes, ce qui vous permet d’améliorer vos niveaux de service et d’optimiser vos stocks.

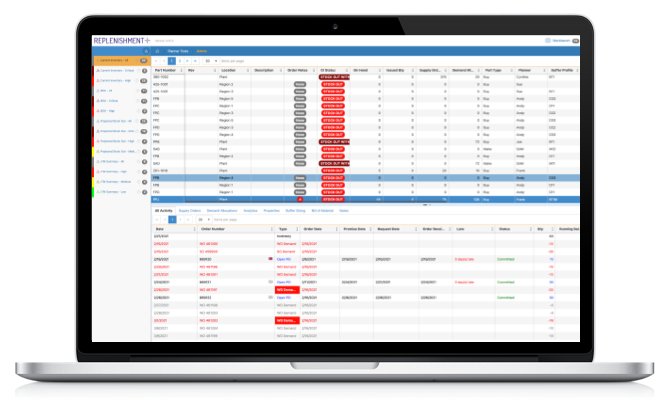

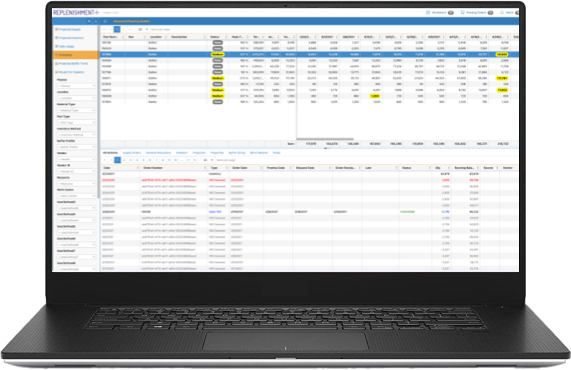

Conçue en accord avec les principes de Demand Driven MRP, nous proposons une solution multi-échelon qui identifie automatiquement les positions stratégiques des stocks dans votre chaîne d’approvisionnement. Grâce aux fonctionnalités de pilotage et d’analyse, vous pouvez concentrer l’attention des planificateurs et opérationnels sur ce qui compte vraiment. Replenishment+ est la première solution de planification des besoins matière entièrement conforme à être certifiée par le Demand Driven Institute.

L’intégration est facile, Replenishment+ s’intègre à tous les principaux systèmes ERP, tels que SAP, Sage, Microsoft Dynamics, Infor, et autres. Pour en savoir plus sur notre solution native pour NetSuite, cliquez ici.

Augmentez le taux de service

Optimisez votre inventaire

Réduisez les besoins en fonds de roulement,

Réduisez les délais

Préparez l'avenir de votre planification des matériaux avec APM, le module de planification avancée Replenishment+.

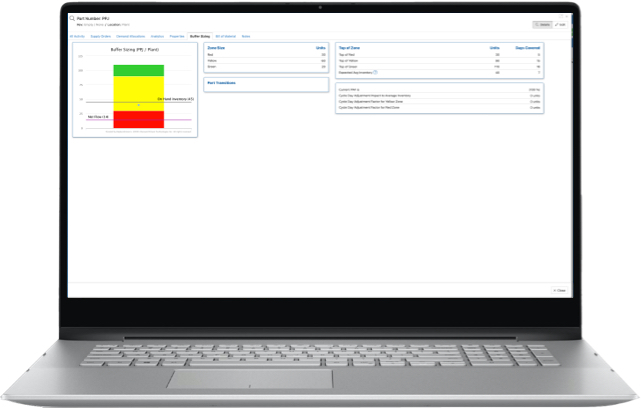

Le module de planification avancée (APM) de Replenishment+ offre un aperçu plus approfondi de l’activité des buffers à long terme pour une stabilité opérationnelle accrue et une amélioration des niveaux de stocks, de service et des délais. Ce module complémentaire permet de planifier les événements futurs connus, tels que les vacances ou les promotions, et de procéder aux ajustements nécessaires.

Replenishment+ : Logiciel de planification Demand Driven MRP

- Protégez-vous contre les fluctuations et les ruptures de stock

- Planifiez facilement les ajustements anticipés comme les pics saisonniers

- Libérez les fonds de roulement en réduisant les matériaux achetés et les stocks inutilisés

- Éliminez les conjectures causées par des prévisions inexactes et prenez des décisions basées sur des commandes réelles

- Remplacez les feuilles de calcul déconnectées tout en offrant une visibilité de bout en bout

- Contrôlez et gérez la planification du matériel sur plusieurs sites