Demand Driven Sales and Operations Planning

Adapt to ever changing market dynamics and ensure the alignment of materials and capacity to expected conditions. With Replenishment+ APM you can now align materials and production resources to true demand, maximizing customer service and throughput performance. Our Advanced Planning Module (APM) provides deep insight into expected buffer activity and implications for materials management and production scheduling. This enables timely and effective monitoring and adjustments to the Demand Driven Operating Model, dramatically reducing the impact of variation and improving operations stability and productivity.

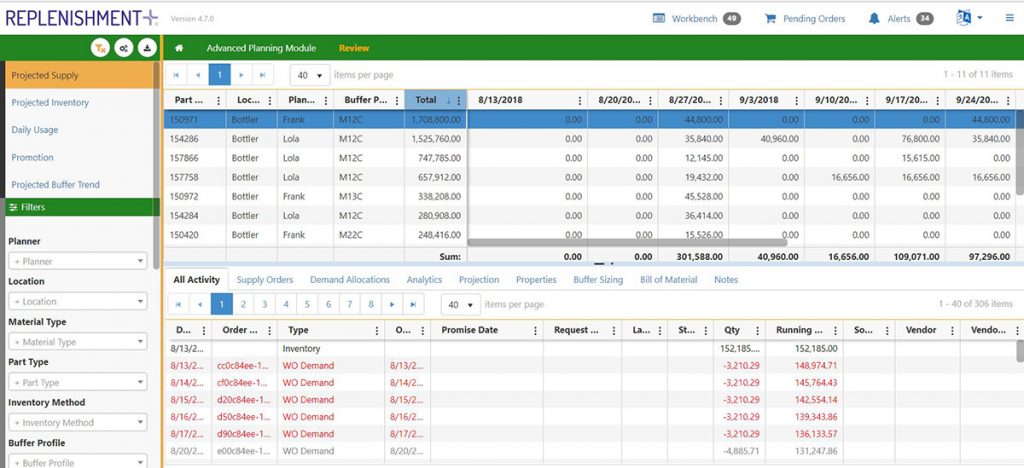

Projected Supply

See expected production or vendor supply order requirements.

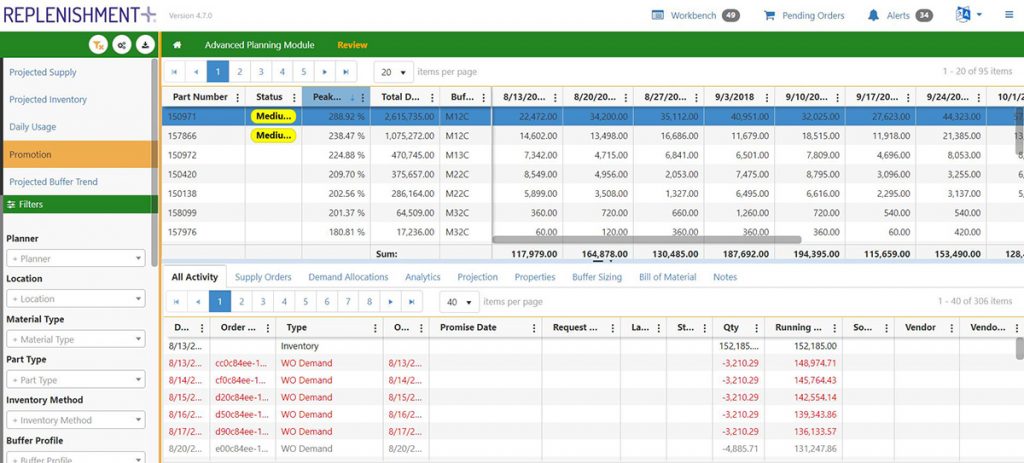

Easily see periods where demand peaks beyond defined alert thresholds.

Projected Inventory

Highlight inventory exposures enabling configuration changes to the Demand Driven Operating Model.

See Projected Inventory Gaps

See buffer distribution and projected gap between on hand inventory and target inventory.

“The Replenishment+ Advanced Planning Module provides an excellent platform for Sales and Operations Planning in a true demand driven environment”.

See how your items react in a DDMRP Environment

Simulation Request