Materials Planning Software

Align Supply and Demand with Optimized Inventory Management

Companies have invested billions in ERP systems — yet inventory turnover rates have been stagnant for more than two decades. Materials Planning in Intuiflow helps manufacturers optimize their entire supply chain to reduce bottle necks and improve on-time delivery. Drive results with actionable recommendations that leverage AI/ML, intuitive alerts, and the right planning method for your business needs. Get the inventory where and when you need it based on real-time sales order data and avoid piles of obsolete inventory bloating your balance sheet.

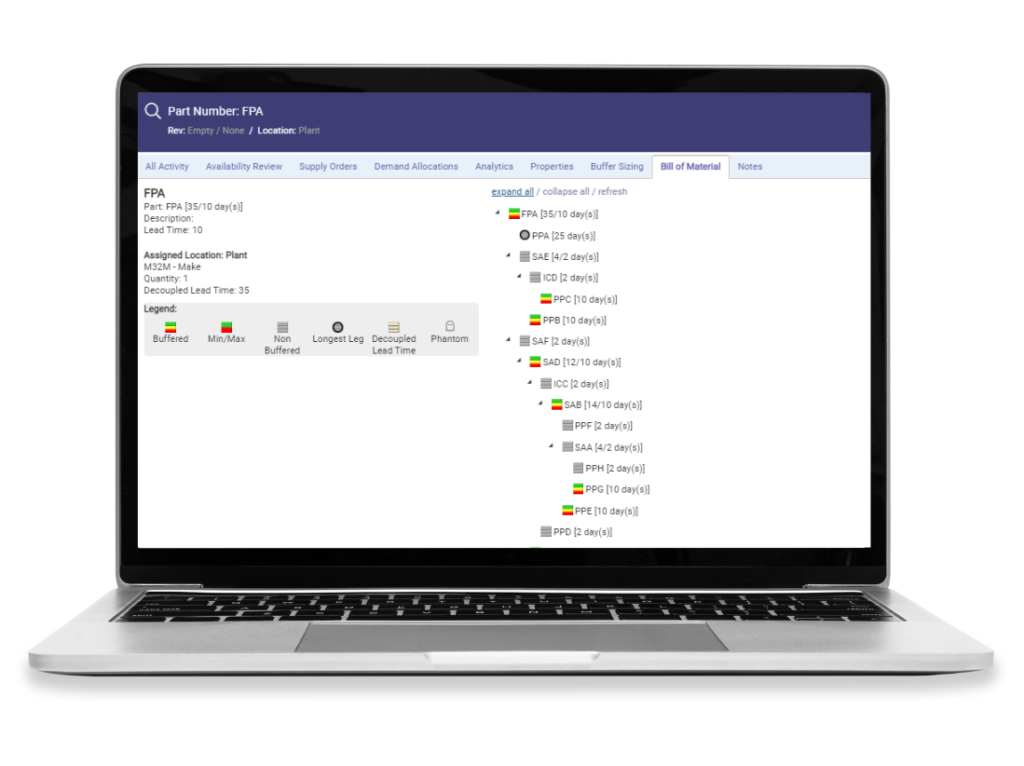

Materials and Inventory Management

Materials Planning is designed to streamline the process of creating and managing orders in a demand pull inventory system, consistent with the DDMRP methodology. Intuiflow takes a revolutionary approach to analyzing the bill of materials, decoupling explosion between strategic stock points, and intelligently reducing effective lead times. It provides visibility and management of strategic non-stocked parts through a highly visual system using color, while also alerting you to potential issues before they cause delays. Whether managing strategic inventory, MRO, or engineer-to-order production, Intuiflow offers simple yet powerful tools. Take a look at the functionalities of Materials Planning:

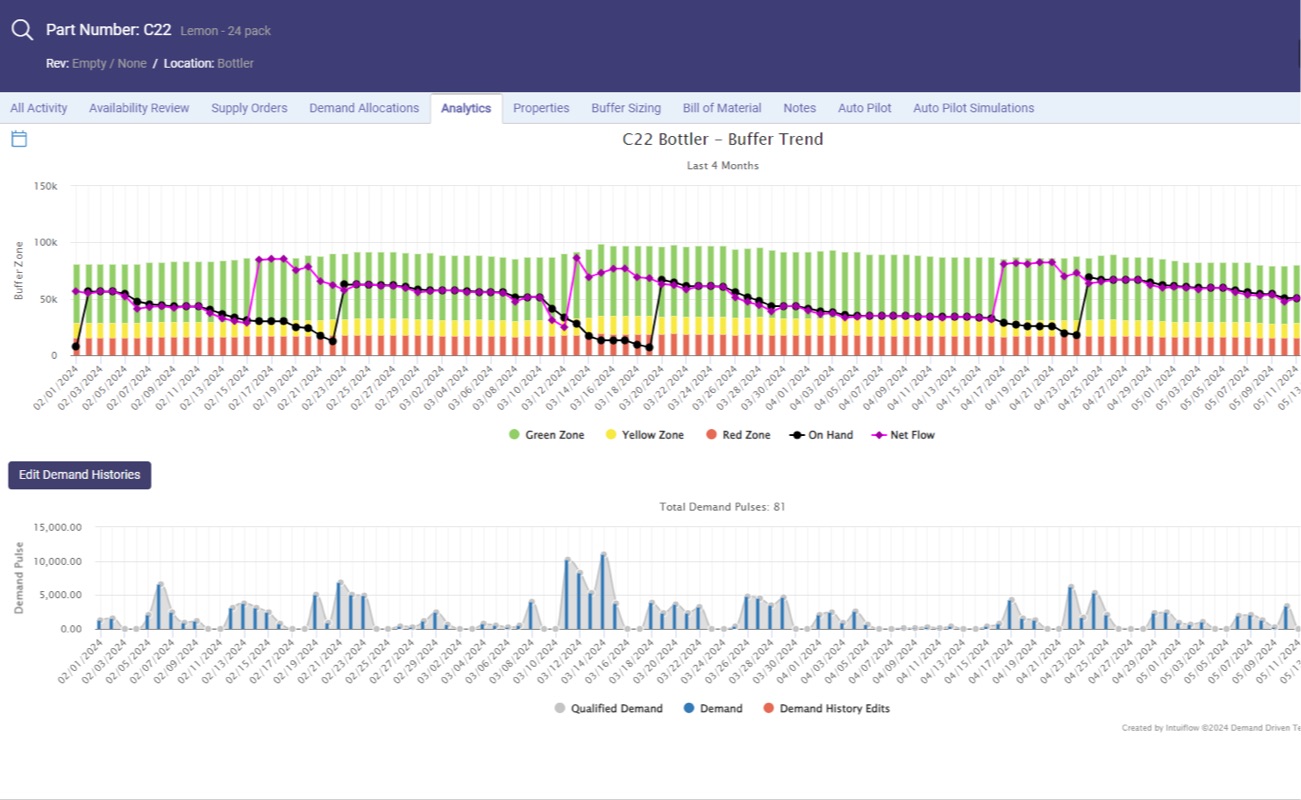

Simplify Demand Driven Planning

Become More Responsive

Effective inventory management starts with controling lead times. Our advanced AI/ML driven logic automatically identifies opportunities compress planning horizons while taking advantage of current inventory levels. The ability to identify where to strategically position inventory will let you dampen the effect of variations and mitigate the dreaded ‘Bullwhip Effect’.

Optimize Daily Ordering

Managing orders is at the heart of efficient inventory management. Quickly prioritize and act on daily orders with intuitive recommendations that ensure the smooth flow of materials throughout your supply chain. Automatically incorporate any order constraints associated with a part and reduce your risk of shortages. Use our Load Optimizer to create orders that perfectly fit in that long lead-time shipping container or the truck occupying your limited number of bays. We do all this while respecting order minimums, multiples, and avoid the wasted space in your containers and the time to calculate loads in a spreadsheet.

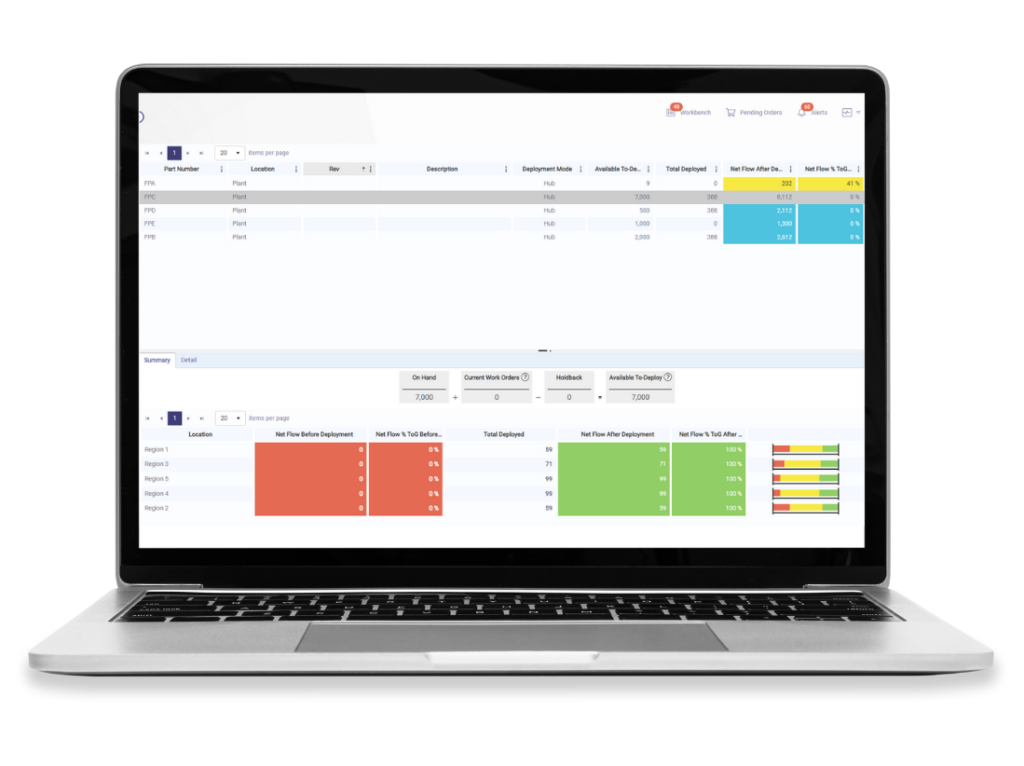

Put Everything in the Right Place

Ensure that your inventory is where it needs to be when it matters most. With real-time visibility across your entire supply network, our Materials Planning module helps you optimize product placement at every distribution center, warehouse, and retail location. No more guesswork or political decisions—just data-driven insights to ensure the right quantity of products is always available. Use prioritized share logic to deploy inventory from upstream locations based on downstream demand, ensuring seamless product flow and availability during peak promotions.

Easily Manage Unexpected Issues

Lifecycle management is crucial to avoid the pitfalls of excess inventory and write-offs. Whether managing the transition to a new product or handling seasonal items, it’s essential to plan for the entire lifecycle of your materials. With Intuiflow, you can seamlessly manage new items with no demand history, replacement parts, or parts nearing retirement. Automatically link related parts, specify start and end dates, and let the system handle the lifecycle of your materials, ensuring a smooth transition without accumulating obsolete inventory.