You’re familiar with comparative tests: when you’re looking for the latest fashionable technological gadget to fall for, you browse comparative tests and user reviews! To help you select the best...

“Ah, if only production would do as they’re told,” sighed one of our customers, a supply chain director, recently. I spent thirty years on factory management committees, so I can...

In all fields, and the supply chain is no exception, propaganda has an enormous influence. We are subjected to it in our social life, in our consumer incentives, in the...

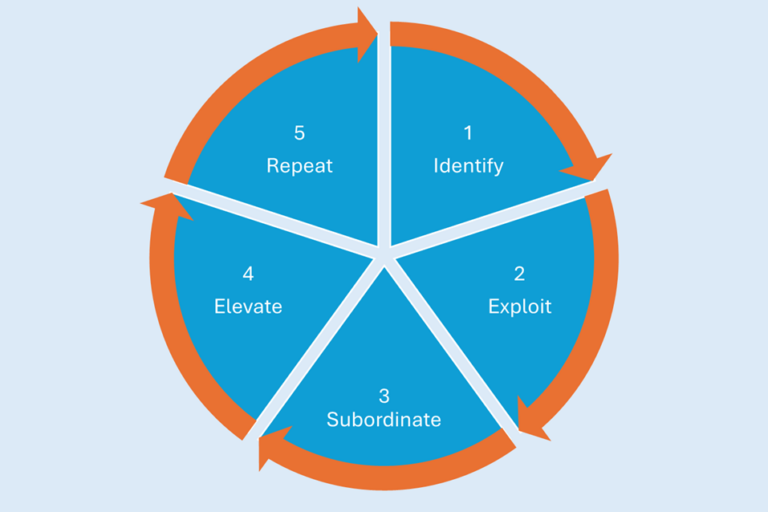

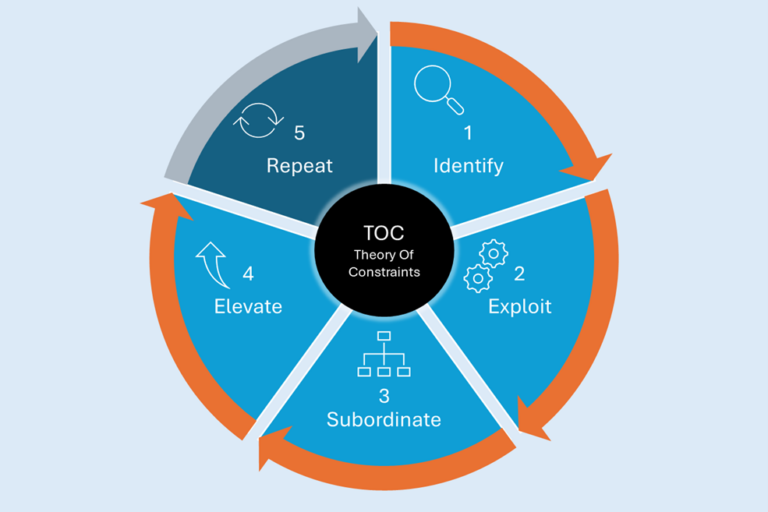

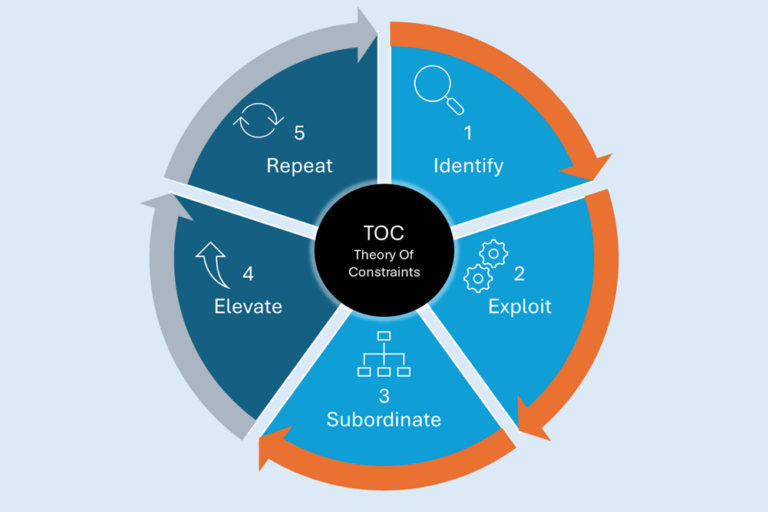

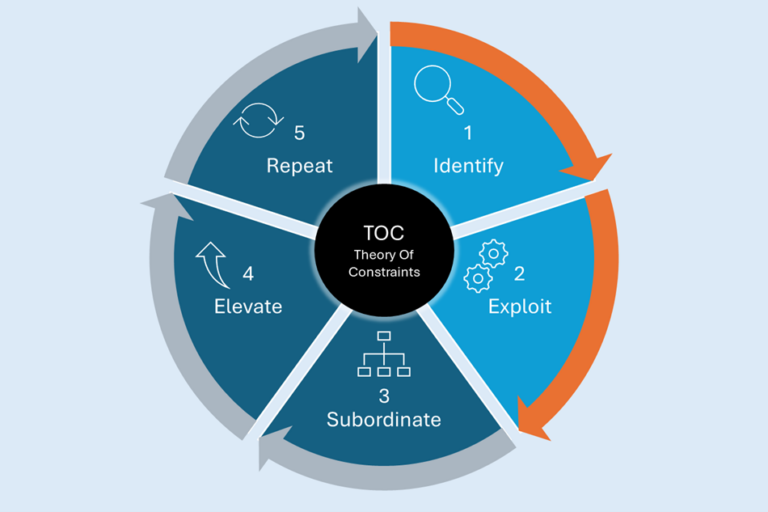

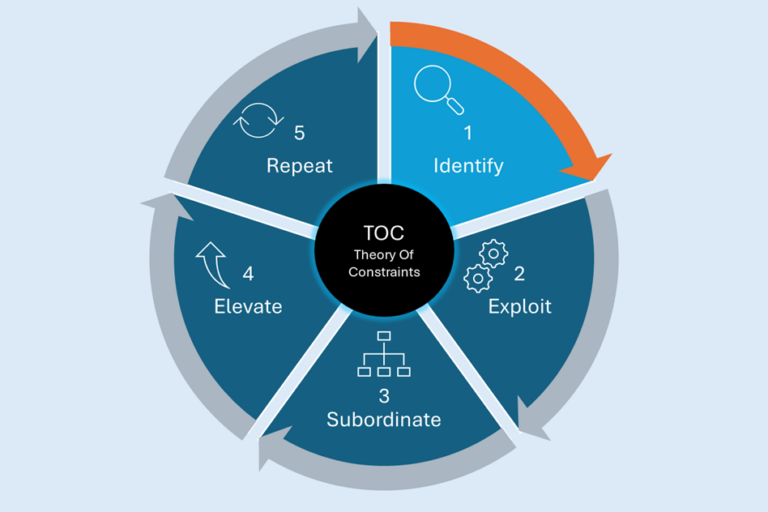

Are you familiar with the “five focusing steps”? This approach is at the heart of the Theory of Constraints (TOC), the school of thought initiated by Dr. Eli Goldratt, author...

As the year draws to a close, now is an ideal time to evaluate potential supply chain software upgrades. Proactively assessing new supply chain solutions can offer powerful advantages for...

Are you familiar with the “five focusing steps”? This approach is at the heart of the Theory of Constraints (TOC), the school of thought initiated by Dr. Eli Goldratt, author...

Are you familiar with the “five focusing steps”? This approach is at the heart of the Theory of Constraints (TOC), the school of thought initiated by Dr. Eli Goldratt, author...

The “Five Focusing Steps” are a kind of counterpart to Deming’s PDCA – Plan Do Check Act. There are five steps for driving the improvement process. In this case, the...

Are you familiar with the “five focusing steps”? This approach is at the heart of the Theory of Constraints (TOC), the school of thought initiated by Dr. Eli Goldratt, author...

There’s no point in running… In your production resources, in your production orders, among your suppliers, you have hares and tortoises. The trick is to get there on time (yes,...

A chain, or network, is a system that brings together players with different motivations. A supply chain comprises suppliers and customers. Both want to maximize their profits, which can be...

Numerous software solutions, and not the least, are available to optimize inventories. Just Google “inventory optimization” and you’ll see a wide range of tools aimed at tackling stock management. In...

In mathematics, the law of large numbers is a fundamental principle of probability theory, which states that when a random experiment is repeated many times, the average of the results...

During the Paris 2024 Olympic Games, all kinds of predictions were made about the medal chances of different countries. Some have even developed algorithms, predictive models and business planning tools,...

Even if they don’t know it, the notion of a decoupling point is very familiar to your favorite pizza chef. Last week I made a call to the excellent pizzeria...