Understanding Safety Stock Calculation

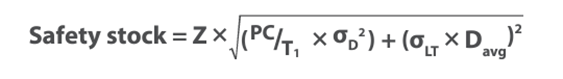

Strategic inventory positioning is critical in supply chain management, and one of the most important aspects of this is determining safety stock. Statistical formulas are commonly used to size safety stocks, helping businesses account for demand variability and lead-time variability. A well-known formula used in inventory management incorporates these variability assumptions, ensuring that businesses maintain an adequate buffer without overstocking.

One of the key elements in these formulas is the Z-factor, which helps target service rate optimization. The Z-factor values are predetermined based on the level of service a business wants to achieve. For example, a 100% service rate would require an infinite Z-factor, which is not realistic. A more reasonable target value for businesses aiming for a high service rate of 99.9% is a Z-factor of 3.09.

For further reading on safety stock calculation, a well-articulated article is available here: MIT Safety Stock Calculation.

Practical Challenges in Safety Stock Calculation

Throughout my career, I have attempted to use these formulas and often found myself adjusting or down-censoring the values obtained. Many of these safety stock calculation formulas are inflationary, which means they tend to overestimate stock levels. Despite this, they do offer the advantage of differentiating between items with high and low variability, which is a significant improvement over simplistic strategies such as maintaining a fixed number of days in stock without considering fluctuations in demand forecasting.

The Role of Buffer Sizing and DDMRP in Inventory Management

In demand-driven material requirements planning (DDMRP), buffer sizing plays a crucial role in ensuring efficient inventory management. When determining the red zone of a buffer, a more pragmatic approach is adopted. Instead of relying solely on static formulas, items are categorized based on lead-time variability and demand variability. The red zone is then established using securing percentages that have been validated through experience. This approach enables dynamic adjustments based on real-world data rather than relying solely on theoretical models.

One advanced approach to buffer sizing is Auto-Pilot inventory management. This automated system uses AI in supply chain operations to simulate various inventory scenarios, enabling businesses to optimize their safety stock dynamically. By leveraging generative AI, Auto-Pilot can predict inventory needs based on real-time demand forecasting, allowing for automated supply replenishment while minimizing excess stock.

Case Study: Real-World Safety Stock Calculation Example

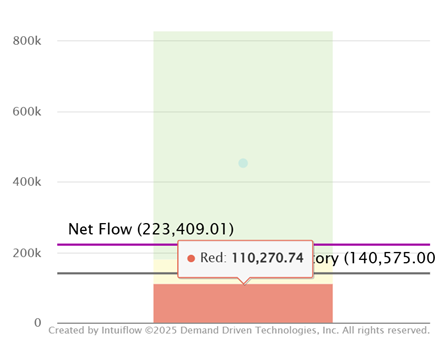

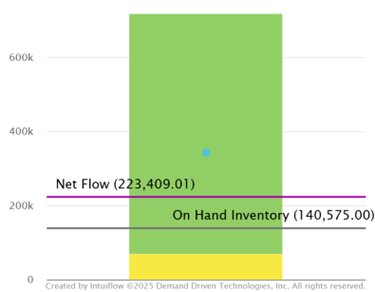

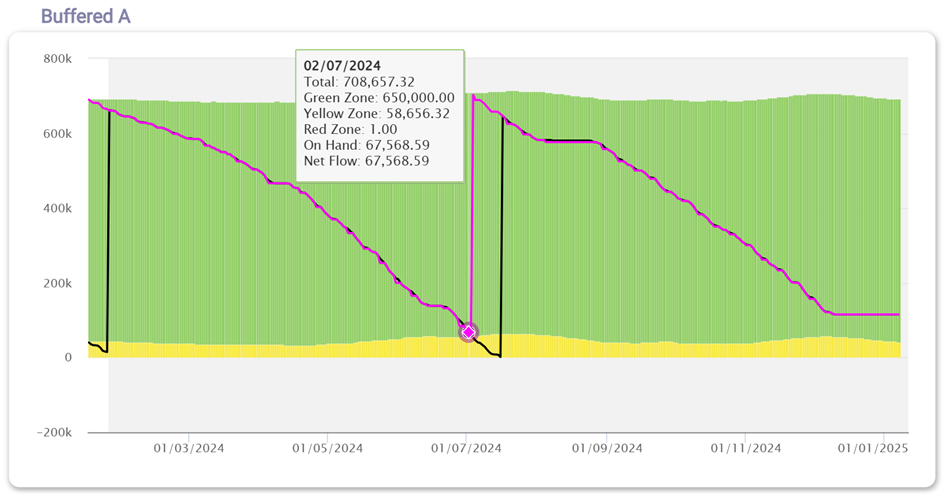

Let’s examine a random item to illustrate the practical application of safety stock calculations. Using a traditional formula targeting a 99% service rate (Z-factor of 2.33), we initially calculated a red zone requirement of 110,000 units.

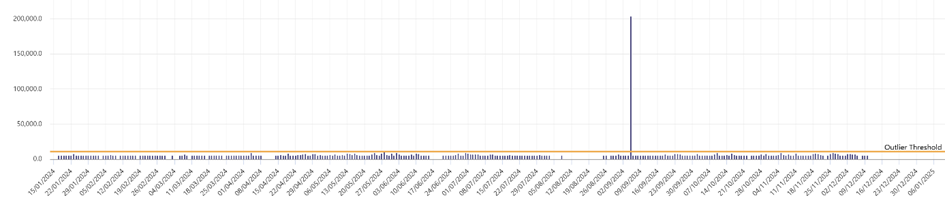

Adjusting for Anomalies

Upon closer inspection of the demand history, we identify an outlier—a one-time spot order that skews the overall data. Since this spot order does not need to be included in the stock sizing strategies, we clean up the historical data to reflect normal demand patterns.

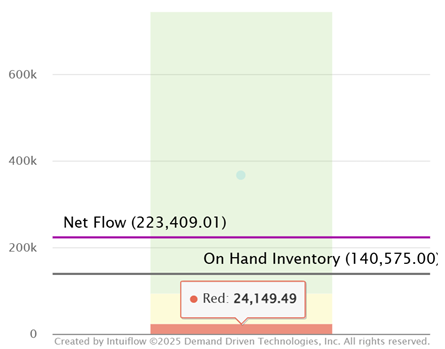

After removing this anomaly, the safety stock calculation formula lowers the red zone requirement to a more reasonable 24,000 units.

The Role of Automated Systems

Next, we compare our findings with the Auto-Pilot function in Intuiflow’s integrated sizing system. Surprisingly, the system does not generate a red zone for this item. Upon investigation, we realize that this item has a very high minimum order quantity. With such a large green zone, maintaining a red zone is unnecessary. A retrospective analysis over the past year confirms that we could have saved €30,000 in inventory value by eliminating the red zone.

The Challenge of Minimum Order Quantities

While reducing the red zone provided cost savings, the primary challenge with this item was minimizing the minimum order quantity. This example highlights the importance of considering factors such as lot size and minimum order quantities when determining safety stock. Many traditional formulas fail to account for these constraints, leading to suboptimal inventory decisions.

Lessons Learned: Optimizing Inventory Management for the Long-Term

1. Clean Up Historical Data Before Applying Formulas

Before applying any safety stock calculation formula, it is essential to ensure that demand history is free from anomalies. Unusual demand spikes or one-time spot orders can distort calculations, leading to inaccurate buffer sizing.

2. Question the Limitations of Traditional Formulas

While statistical formulas may seem scientific and reliable, they often operate as black boxes. Many do not factor in real-world constraints such as lot size and minimum order quantities. Incorporating supply chain automation tools and AI-driven demand forecasting can help overcome these limitations by providing more realistic and adaptive stock sizing.

3. Use Dynamic Adjustments for Inventory Optimization

A classic DDMRP approach, which accounts for lead-time variability and allows for ongoing optimization, is often a more practical solution. Businesses that embrace dynamic adjustments rather than static calculations can improve their inventory management and reduce unnecessary stock investments.

4. Leverage AI and Automation for Smarter Decisions

Modern supply chain management benefits significantly from AI-driven insights. Generative AI can analyze user behavior, predict fluctuations in demand, and recommend optimal inventory levels. Artificial intelligence in supply chain operations also enables businesses to implement automated supply adjustments, ensuring inventory is continuously aligned with actual demand.

5. Conversion Rate Optimization Services and Landing Pages

Effective inventory management does not operate in isolation. Businesses looking to maximize their order fulfillment efficiency should also consider conversion rate optimization services. By refining landing pages and analyzing customer interactions, businesses can better predict demand trends and improve inventory accuracy. Increasing conversion rates directly impacts inventory turnover, ensuring products move efficiently through the supply chain.

The Future of Safety Stock Calculation

The future of inventory management lies in intelligent automation and AI-driven decision-making. Companies that adopt an automated system for safety stock calculation and demand forecasting will gain a competitive advantage. By strategically integrating artificial intelligence in supply chain processes, businesses can:

- Reduce excess inventory while maintaining high service levels.

- Optimize proper position sizing for each SKU based on real-time demand data.

- Enhance supply chain operations with automated tools that dynamically adjust stock levels.

- Minimize the dollar amount tied up in unnecessary inventory, freeing up capital for other business needs.

Conclusion

Safety stock calculation is a critical component of effective inventory management. While traditional statistical formulas provide a foundation, they often fail to account for real-world complexities such as minimum order quantities and dynamic demand patterns. By leveraging AI-driven automation tools and implementing demand forecasting techniques, businesses can optimize their supply chain operations more efficiently.

As businesses continue to evolve, integrating conversion rate optimization services with strategic inventory positioning will become increasingly important. The synergy between data-driven inventory management, automated systems, and user behavior insights will pave the way for smarter, more cost-effective supply chain solutions.

In the end, the key to success in safety stock calculation lies in adopting a holistic approach—combining historical data analysis, AI-driven insights, and automation to achieve optimal stock levels. By doing so, businesses can reduce costs, increase efficiency, and enhance order fulfillment rates in the long term.