In our factories, a practice has become established: short-interval animation. Team meetings are held with operators, reviewing what has happened in the last few hours, the team’s priorities for the coming shift, the status of actions in progress, and problems to be solved. This same ritual is repeated by sector and at the plant level. It’s a daily routine.

This process has its advantages and disadvantages.

It’s very (sometimes too) focused on the short term: adapting operations for the next few hours. It’s not designed to drive fundamental improvements – for that, you’ll need other processes such as project teams, kaizen events, etc.

Benefits of Short-Interval Animation

However, the benefits are numerous:

- Alignment of teams through transparency of information.

- Continuous adaptation, ensuring operations stay on track.

- Real-time issue resolution, reducing downtime and inefficiencies.

This is why short-interval animation has become the norm in most companies, allowing them to maintain flexibility and efficiency in rapidly changing environments.

A Conventional Supply Chain Orchestrated at Long Intervals

In conventional supply chain management, the pace of adaptation is slower. The structure follows:

- Annual budget planning for financial alignment.

- Monthly Sales & Operations Planning (S&OP) to balance supply and demand.

- Weekly master production scheduling for operational alignment.

- Daily execution monitoring to track performance and address minor adjustments.

Additionally, companies impose frozen horizons, limiting their ability to quickly react to market shifts or disruptions.

Is this Model Right for a VUCA World?

In a world defined by Volatility, Uncertainty, Complexity, and Ambiguity (VUCA), can businesses afford to defer their adaptation to scheduled intervals?

While S&OP, MPS, MRP, and PAC have served organizations well for decades, much of their rigidity stemmed from technological constraints of the past.

For instance, in the 1980s, to execute S&OP, companies needed to:

- Wait until the end of the month for sales data.

- Extract data manually from internal systems.

- Manipulate it in spreadsheets to create reports.

- Engage in lengthy discussions with sales and production teams.

- Reconcile inventory and demand forecasts before finalizing decisions.

This long, painful process was prone to errors and based on outdated information by the time decisions were made.

I was trained in it as part of my APICS training in the late 80s – damn! almost 40 years ago… But in the 21st century, do we still need to operate this way?

The answer is no.

Real-Time Data Management – How Do We Use It?

Modern technology and automation have changed everything. Today, companies have access to up-to-date, reconciled data in real-time.

However, simply having data isn’t enough—it must be made actionable.

The Real Challenge

- Real-time data without strategic action leads to chaos.

- Poor data utilization results in information overload.

- Delayed decision-making weakens adaptability.

The key to success is not just collecting data, but knowing how to leverage it effectively.

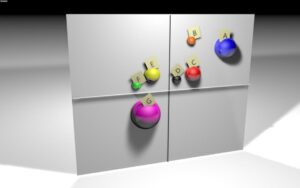

Short-Term Adaptation: Short-Interval Decision-Making

Let’s return to the workshop environment. If you’re part of a short-interval standing meeting, you need accurate, real-time information to make critical decisions within the next few hours.

Key Questions for Effective Short-Interval Planning:

- Which products require immediate prioritization?

- Do we have all necessary components, tools, and workforce availability?

- Are there bottlenecks requiring urgent reallocation of resources?

- How do we prevent overproduction or inefficiencies?

Optimized Strategies for Short-Interval Planning:

- Pull flow systems to ensure efficient production sequences.

- Constraint-based management to tackle bottlenecks effectively.

- Queuing & visual time buffers to highlight advance/delay/priority status.

By integrating these elements, teams can maintain autonomy and flexibility, adjusting workflows in real time.

Medium & Long-Term Decision-Making: Adaptation at Scale

Why Long-Term Decisions Must Be More Agile

- Decisions impacting longer horizons require higher effort and risk.

- Strategic changes cannot afford long, bureaucratic delays.

- New data insights must trigger immediate adaptations rather than waiting for a month-end review.

Best Practices for Real-Time Strategic Planning

- Automate data updates for forecasts, supply risk projections, and capacity assessments.

- Detect key inflection points early to avoid last-minute reactive decisions.

- Evaluate alternative scenarios in real time using predictive analytics.

By leveraging business intelligence tools and AI-driven insights, companies can maintain a continuously updated strategic roadmap, ensuring that they stay ahead of disruptions rather than reacting to them.

The Future: Short-Interval S&OP

I believe that the era of rigid, time-consuming S&OP processes is coming to an end.

In today’s fast-paced environment, the ability to adapt instantly is a critical success factor.

How to Implement Short-Interval S&OP Successfully

- Empower teams with real-time decision-making authority.

- Eliminate excessive reporting loops that slow down action.

- Automate reconciliation of data across functions.

- Use AI-driven analytics to highlight immediate action points.

The key takeaway?

Companies need to move towards a fluid, adaptive decision-making model, rather than waiting for fixed review cycles.

Final Thoughts: Why Short-Interval Planning Matters

- Faster response times to changing market conditions.

- More resilient operations with real-time adaptability.

- Improved resource utilization, avoiding bottlenecks and overproduction.

- Competitive advantage through smarter, data-driven decision-making.

The time for traditional, slow-moving supply chains is over.

Short-interval planning is the future.

What’s Next?

- Subscribe for more insights on supply chain & manufacturing excellence. Fill out the form in the right side bar!

- Get in touch to discuss how we can help your business transition to real-time planning.