Ken Titmuss has helped more than 200 companies with all aspects of their manufacturing planning and control systems and provided their employees with courses to raise their level of understanding of Operations Management and Supply Chain Management. Most of Ken’s work has been in Southern Africa, but more recently, he has run programs in Namibia, Botswana, Kenya, Zimbabwe, Nigeria, USA, UK, Ireland, France, India, Australia, Dubai, Saudi Arabia, Jordan, Mauritius, Singapore, and Lebanon.

The State of Manufacturing In 2020

It’s a great time to be in manufacturing. Sure, the sector has a few issues – like an ongoing talent shortage and the never-ending uncertainty in global markets. But all in all, things are looking positive in many parts of the world. According to the Global Business Wire, the global manufacturing industry is growing at a healthy rate of 3% year over year and contributing 30% to the global GDP.

But, before we get too optimistic, we have to accept that our success is hindered by a problem our industry has been struggling with for decades: forecast inaccuracy.

In this first in a series of posts, I want to lay out the challenge and introduce you to the solution. Then, in future posts, I’ll peel back some of the layers so you can see how everything works. For an audio introduction to the topic, you can also download my podcast, An Introduction to DDMRP.

The Three Rules of Forecasts

If you’re in manufacturing, you’re probably well aware of the three rules of forecasting:

1. They are wrong.

2. The further out you go, the more wrong they will be.

3.The more detailed, the more wrong they will be.

In my more than 30 years of helping manufacturers improve their material requirements planning processes, I’ve rarely seen forecast accuracy rise above the 70% mark at the SKU level, using traditional approaches to materials and production planning. Since I’ve made continuous improvement my life’s work, I was compelled to know why.

It’s A VUCA WORLD

Before we go into where my search for answers led me, let me make one thing clear. Forecast inaccuracy isn’t the fault of sales or your product managers – at least not completely. We live in a VUCA world, so there’s no sense in waiting for someone else to fix the problem.

If you’re not familiar with the acronym VUCA, it stands for Volatile, Uncertain, Complex, and Ambiguous. No amount of sales training or forecasting process improvements can entirely make up for the VUCA nature of business. In fact, when production planners try to improve upon the forecasts they get from sales, they usually make things worse. They don’t have any better insights into customer demand levels and market trends. And, the spreadsheets they use are error-prone, unaudited, and disconnected from the spreadsheets used in other parts of the supply chain.

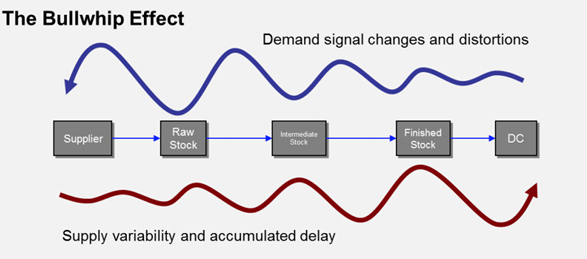

This is compounded by nervousness in the supply chain, where high-level changes in the master production schedule lead to amplified changes in timing and quantity at lower levels. This creates the bullwhip effect that causes the fundamental enemy we must confront: not enough of the right inventory and too much of the wrong.

Source: Demand Driven Institute

Winning The WAR

Not to get too carried away with military analogies, but throughout history, the tides of war have often turned when one side discovered an advancement that gave them the advantage. Many of these advancements required them to turn their backs on traditional methods.

To win our modern supply chain war, we need to lose sight of our reliance on forecasting as the primary input to production planning. The way we do this is through a concept called Demand Driven Material Requirements Planning, or DDMRP.

DDMRP uses strategic decoupling buffers to dampen the bullwhip effect. Think of two children holding opposite ends of a jump rope. Alternately pumping each side up and down causes the rope to behave like the bullwhip. Now, a third child comes along, and (without getting hurt) steps on the rope. The rope still oscillates between that child’s foot and the other children’s hands, but the waves are much smaller, with much less destructive power behind them.

In my next post, we’ll go deeper into how this decoupling works, and more importantly, how to decide where to place these buffers. In the meantime, feel free to reach out to me with questions either on LinkedIn or on my website.

Ken Titmuss is a team member of Demand Driven Africa (a division of PSQ CC), a supply chain specialist enterprise that provides DDMRP training, consultation and implementation using Demand Driven Technologies software product Replenishment+®. With successful implementations already completed, and a growing number of supply chain personnel trained, Demand Driven Africa are leaders in the field offering:

- DDMRP Consulting

- DDMRP Training

- DDMRP Implementation

- Other Supply Chain Training & Consultation