This case study was written by the Demand Driven Institute.

Most often, inventory management methods are dictated by the principles of the IT system a company uses. Typically, this is the MRP, which became widespread in the 1980s. Most MRPs today are outdated, as they have not changed much since their inception.

Since 2012, the DDMRP methodology has been gaining popularity. This is an innovative technique that focuses on real demand. DDMRP helps a company:

- be flexible

- cover market demand as much as possible

- stay competitive and profitable

Xabier Tudanca, Director of Purchasing and Logistics at the Satuerca Group (SAT), presented his experiences with DDMRP and Intuiflow at the Demand Driven World Conference. This conference focused on Supply Chain Management in manufacturing and distribution companies.

In this article, we’ll review the specific production processes that SAT relies on, why the company needed a new inventory planning tool, and what it has achieved with DDMRP.

About the Satuerca Group (SAT)

SAT was founded in 1967 and now is currently engaged in horizontal forging (parts between 50 g-2 kg) and machining. Product range includes bearings, gears, clutch bodies, cams and special nuts. The company’s main customers are Renault, Volkswagen, and other well-known automotive businesses.

Hot and semi-hot forging of a variety of steel pieces takes place in the SAT factories. Two of these factories are in Spain and one is in Romania. Factories have a fully integrated manufacturing process from raw material to finished product.

The Need for a New Inventory Planning Tool

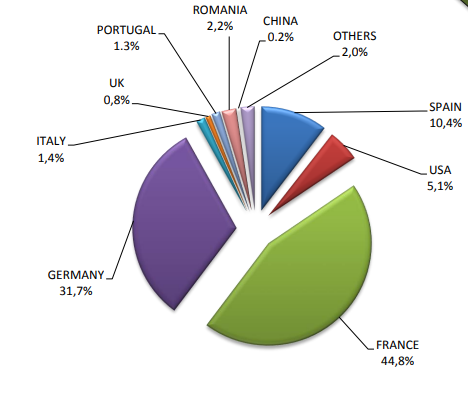

The distribution of SAT products covers countries across Europe and the United States.

SAT’s production facilities include:

- Horizontal forging

- Heat treatments: Annealing, Quenching and tempering,

- Isothermal annealing, Normalized

- Shot blasting

- Automatic 100% inspection (2D and 3D)

- Surface treatments

- Machining

Technical characteristics encompass:

- Forging Temperature 1.200 ºC / 100 to 150 parts per minute

- Lead Time 5-10 days

- Raw Material: round steel bars from 19mm to 55mm, 23.000 Tn / year 60 references

- 400 finished products

The company’s sales for 2012 amounted to 31 million Euro. For 2013, sales rose to 35 million Euro, and in 2014, 39 million Euro. From year to year, SAT’s top management faced a situation where customer forecasts/orders were varying even on the due date. There were delays and shortages of raw material deliveries, over stocks of finished products.

The company needed an inventory management tool that would manage this information on a daily basis:

- Stock levels

- Detection of new Work Orders (WO) requirements

- New raw material purchase requirements

- Which raw material open supply orders need to be controlled

- In Process WO that need to be expedited

Planning Pain Points

Until 2012, planning was dependent on a single managers’ analysis, then from 2012 to 2013 Excel was used. Since 2013 until present day the company’s top management has decided to manage inventory using the DDMRP methodology.

The Switch to DDMRP

After analyzing the demand and the frequency with which it occurs, SAT set the following tasks:

- Change in the way DEMAND is understood

- Forecast/Orders beyond a reliable horizon are no longer considered

- Only committed orders (date and quantity) are considered DEMAND

To execute this Demand Driven transformation, SAT took the following steps:

1. Strategic Inventory Positioning

Strategic inventory positioning involves the process of placing production stocks at strategic locations in the supply chain, from raw materials to finished products. At this stage, it is possible to achieve a lead-time reduction, as well as to replace all data based on an inaccurate forecast.

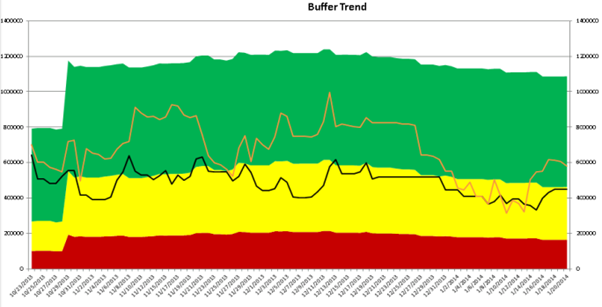

2. Buffer Profiles and Level Determination

Demand driven buffers help protect supply chain flow against variability and uncertainty. Profiles are divided:

- by destination: buy, make, distributed

- by variability: low, medium, high

- by lead-time: short, medium, long

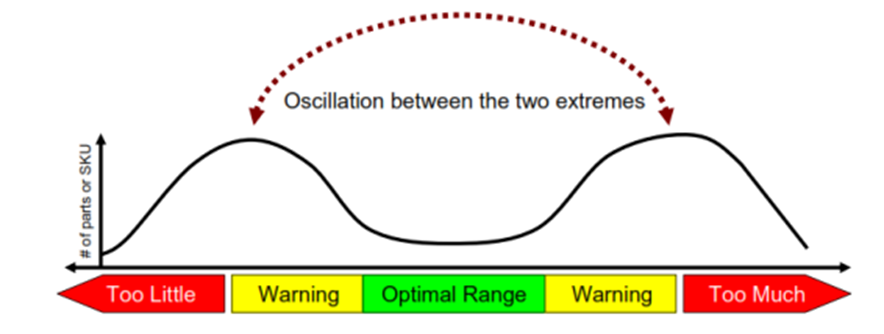

Level determination involves setting the level of replenished parts in the buffer. During the implementation, the following levels were established:

- Red and yellow zones – 5 working days

- The green zone is a month’s supply

- Warning System – 10 days

3. Dynamic Adjustments

Buffers are updated automatically, at least once a day (without management intervention), as well as routinely (with changes in seasonality, promotion, and others).

The Planning Managers must be aware of any extraordinary product change in order to be able to indicate such changes in the buffer parameters. In addition to this, they must review the behavior of the buffers periodically whether readjustments are necessary.

4. Demand Driven Planning

Based on demand-driven planning, managers have a clear vision of demand and quantity of production.

- Daily info vs Weekly info

- Fast realization of whether there is a new need

5. Visible and Collaborative Execution

For planners, it is important to track purchase orders that require special monitoring. SAT processes 60 different raw materials. At this point of the project, the control of the supply of six goods was required, plus seven in the near future. Thus, the manager’s focus was on 18% of SKU.

To develop the most effective strategy for working with customers, these items were divided into four groups, with individual parameters:

CUSTOMER “A”

- Daily forecast for subsequent 3 months

- Daily consumption – Real orders only one day in advance

- Forecast precision – Quite good

- LT = 10 days

- Raw material and finished product buffers

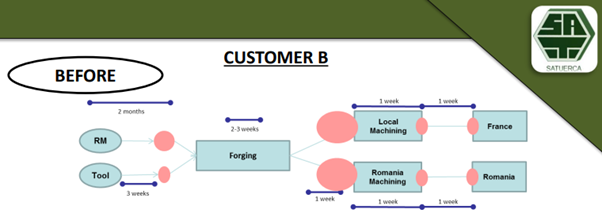

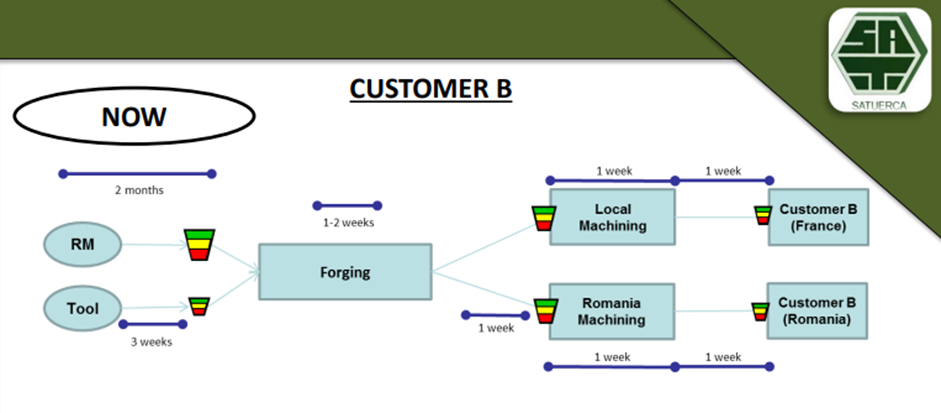

CUSTOMER “B” Forging and Machining

- Weekly forecast for subsequent 6 months

- Consignment stock – daily consumption

- Forecast precision – Bad

- LT = 20 days

- Spike orders

CUSTOMER “C”

- Weekly forecast for subsequent 9 months

- Weekly consumption

- Forecast precision – only the first week is reliable

- LT = 15 days

- 150 references

CUSTOMER “D”

- Enough time available to fulfill the demand from the moment the order is placed.

- Raw material is procured and manufactured to order.

Results with DDMRP

Since September 2013, the company has been using the DDMRP methodology and Intuiflow to manage inventory. Working with Intuiflow, the company achieved:

- Reduction in production planning changes

- Improvements in machine capacity

- Production for one week is planned

- Daily information updated vs weekly information updated

- Improved reaction to changes

- Facilities are used more efficiently while maintaining same service levels (98+%)

- Regulation of the stock levels — stock is available for all production requirements

The best results were achieved by customer B group.

Let’s talk about the customer B group problems before DDMRP implementation:

- Made weekly projections six months in advance

- The stock level was equal to the daily consumption

- Poor forecast accuracy

- Lead-time 20 days

- Constant fluctuations in demand

Bad forecasts meant that stock was out of control, what was needed was out of stock and the forged parts were no longer required. Both factories had urgent orders requiring immediate response at the same time as the implementation.

It was decided to make a 3-week forecast in advance (instead of 6 months) to start the process of manufacturing forged parts. Now, two weeks later, when the forged parts are delivered to Mecanifran, a new forecast tells us whether the new materials will be required for the next process.

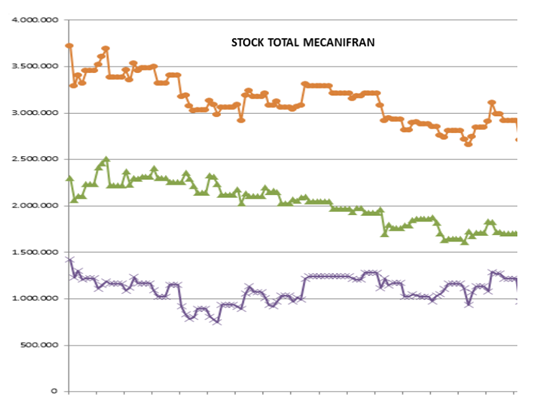

Customer B group results:

- Buffers controlled in every strategic position

- LT reduction up to 50% (from 20 to 10 days)

- Stock reduction ( 3,700,000 parts to 2,700,000 parts) up to 35% in three months

- Distortions that were caused by inaccurate forecasts has been eliminated

- Machine capacity has increased by using only the resources that are needed at the moment.

“DDMRP has improved the management of both information and material flows in production. The Intuiflow system made our work easier thanks to its simplicity and speed of reaction” – says Xabier Tudanca.

Intuiflow was implemented at SAT by CMG Consultores. Read the full case study.