Developing an agile supply chain means reducing lot sizes, reducing lead times, and increasing replenishment frequencies. All this is virtuous to speed up flows, but can conflict with real and legitimate production or transport constraints.

If you’ve been involved in Lean initiatives, you’ve probably faced these trade-offs. Reducing batch sizes increases the number of changeovers, and despite the efforts of SMED initiatives, these have a cost – in time, capacity, loss of material due to cleaning, and so on.

A relevant way to accelerate flows while improving productivity is to implement group planning.

What is it all about?

Constraints and Rules for Planning

The first step is to identify the legitimate constraints and common-sense rules that apply to the planning of our manufacturing or transportation operations.

A few examples:

- In many industries – chemical, pharmaceutical, cosmetic, food, beverage – a bulk product (a juice, a mix, a recipe…) is manufactured and then packaged in multiple formats, brands, language variants. It is not always possible to decouple the stock from this bulk, for good reasons – physical constraints, product stability, etc. It is therefore necessary to combine the requirements for finished products as well as possible to reach a bulk batch size.

- Supplies are procured in sea containers or truckloads, possibly in the form of milk runs, and the volume of this transportation is best utilized by combining pallets of items purchased from one or more suppliers.

- A lacquering line is planned based on a cycle over several days following a color sequence from lightest to darkest.

- Parts cuttings should be combined in the same metal or composite sheet to minimize material loss (placement of shape sets).

- We organize the bar turning of parts by bar diameter and by length in each diameter.

- A consignment stock must be replenished at a customer’s location, and the highest priority items must be combined in a shipping lot.

Application examples are legion, and I am sure by reading these few lines you’ve identified similar cases in your environment.

ERP System Problems

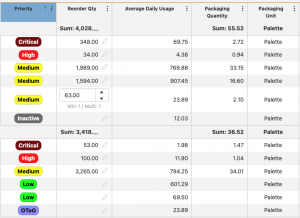

However, it is striking that our preferred ERP systems do not particularly help us to implement this type of logic. For example, our ERP system provides for minimum order or launch minimums expressed in the item code, whereas often the minimum launch should be expressed on a group of items.

For example, a batch of 10,000 L, which corresponds to the size of a reactor, should be launched. On the other hand, one can package small quantities of each packaging variant. If the grouping constraints can be easily respected, the batch sizes per item can be significantly reduced.

It must be recognized that in most companies this type of grouped planning logic is implemented in Excel, with the science that each planner has developed through experience.

Often this logic is also imposed via a master production program firmed up over a long enough horizon to allow the organization of campaigns. However, a firm MPS over a significant time horizon will not meet the need for supply chain agility, and will contribute to amplifying the bullwhip effect.

Some companies have implemented an APS to address these issues, which is often complex and costly, with uneven results.

How to Achieve Agility in the Supply Chain with Group Planning

What is the interest of DDMRP and more broadly of a DDOM for grouped planning? DDMRP greatly facilitates the implementation of group planning, while preserving agility, thanks to several unique features:

- The consistent dimensioning of the stock buffers allows the unambiguous identification of relative priorities.

- Each buffer defines an operating range. This operating range provides the necessary flexibility for grouping.

- The green zones set to the order cycle allow campaign frequencies to be sized for all items, without imposing high minimum order levels at SKU level.

- It is easy to implement a planning wheel logic: a relevant and regular sequence of campaigns, while respecting the red/yellow/green priorities of each item. Over time, the rotation of the wheel will speed up with continuous improvements.

- The permanent visibility of relative priorities allows decisions to be made as late as possible, instead of firming a long horizon: the campaign’s assortment only needs to be put together at the time of its launch. As far as possible, this decision can be delegated to the shop floor, as you would with a Kanban board.

- Multi-level grouping rules along a hierarchy of criteria are easy to implement.

- Time buffers allow to orchestrate combinations of heterogeneous items, made to stock and to order, on critical resources.

- Finite scheduling of control points combines the priorities of stock buffers and sales orders and applies the defined grouping and sequencing rules.

- The projection of the future behavior of buffers for DD S&OP also takes into account the campaign grouping rules, and thus allows for a realistic projection of inventory, service and capacity requirements.

Demand Driven Technologies’ group planning software solutions integrate unique functionalities to put group planning within everyone’s reach, don’t hesitate to contact us!