In last week’s post, we introduced some of the lessons we’ve learned about implementing new supply chain technology. This week, we’ll take a look at some case studies from companies in Russia to the countries of the Central Asian region.

Case #3: The Disappearing Team Lead

As we mentioned last week, the project teams that companies create to manage technology implementations are often fluid. As people are promoted or resign, they leave the project and take their knowledge with them. Another problem often follows soon thereafter: the absence of and/or noninvolvement of the team lead.

“Hello, have you tried to log in?”

“Where?”

I think you want to know more about this dialogue. Here is what happened during one of our projects:

The day before, our client’s team was granted access to Intuiflow. This information was communicated through the team lead.

According to him, everyone had seen all the access information. He assured us they would register and prepare for our meeting the next day — a day we had planned to dedicate to learning.

The next day, it turned out exactly the opposite. None of the planners had followed the instructions of the team lead. What happened? Did the team just ignore it?

We are not talking about leadership qualities here. The manager himself was simply overwhelmed with other immediate responsibilities and did not have time to devote to this task and control what was happening.

Tip: Top management should take a responsible approach to choosing a team lead or project manager. It should be an expert in the role of a project manager, as a center of competence, who can control the team and the implementation of the tasks.

This person must combine both professional and leadership qualities. Moreover, it must be clear that this employee has time in his or her agenda to be able to handle the project. Financial project incentives also encourage the manager to keep track of the project’s progress.

Case #4: Old vs. New

Innovations and modern IT technologies sometimes run up against outdated thinking.

Let’s look at one more real example.

An enterprise had purchased an expensive ERP system to automate business management. The system seemed great — and was expected to significantly improve the company’s situation by increasing the team’s efficiency and the transparency of its business processes.

But let’s face it: Installing and configuring software and re-educating teams is a long and wild journey. In the end, despite all efforts, the new ERP sat idle, and all processes continue to work as before. Employees looked in horror at the new icon on the desktop, not daring to click on it.

In our experience, employees (except the IT department, of course) need more than a short educational session to understand how new systems work or what their role is in the new processes. But there’s a reason why they can’t address these questions: they are afraid that management will perceive it as incompetence.

Everyone wants to show their best. And as the world evolves and changes, prior successes could be cast in a bad light thanks to new systems and methods.

One manager may resist innovation because he has been in business for a long time and has studied many methodologies. He has earned a good reputation among the company and the market. The software may discredit his previous decisions.

Something needs to be done about this — not to demotivate people, but to make them gradually realize the benefits that the implemented IT solution grants.

Here’s why some professionals continue to use outdated methods:

- They’re accustomed to the way things are

- They do not think about the enterprise growth

- They think, “If someone else doesn’t, I won’t either”

- They’re afraid that management will decide they are no longer needed, or that the system will replace them

- The IT department or admins of the new system do not provide comprehensive, appropriate, and periodic staff training

- The management involvement in the process is weak

Tip: Link employees’ activities to the new system, preventing them from returning to their spreadsheets. Bring in motivating and demotivating factors to stimulate work with the new software. It is mandatory to conduct training sessions (LMS systems, gamification, etc.) to facilitate a comfortable process of signing into new working conditions.

Supply Chain Management is Changing

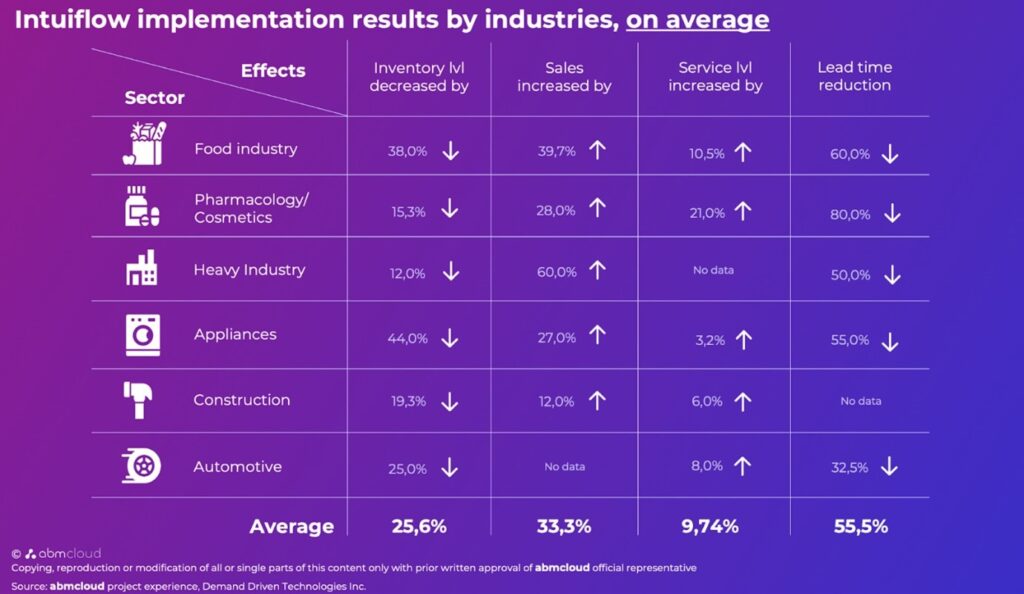

Top management are the ones who are constantly looking for innovations in finance, transport, and labor resources. As for the paradigm shift in inventory management, this is probably not an ordinary story. However, our case studies show a significant financial effect from such innovations:

Intuiflow world implementation results

If you have ever tried to implement IT technologies for supply chain management or inventory management in your company but something went wrong, this is not a problem. There are always a few things you can do to rate where you are now and what to do next. The main thing is not to give up and to understand that you can’t just go with the flow, continuing to use the same methods as 20-30 or even 50 years ago.