Let us Show You a Better way to Agility and Resiliency

Our simulation can deliver remarkable results effortlessly with your data.

Seeing is believing. Request your free-no obligation simulation today, and we will show you how we can save you millions on your inventory. Prevent stockouts and increase your ability to be agile in your environment.

How does it work?

Historical Demand

Populate your data in the template provided below and submit the form at the bottom of the page.. We do not ask for confidential information. However, if you require an NDA, we are happy to provide it.

Review

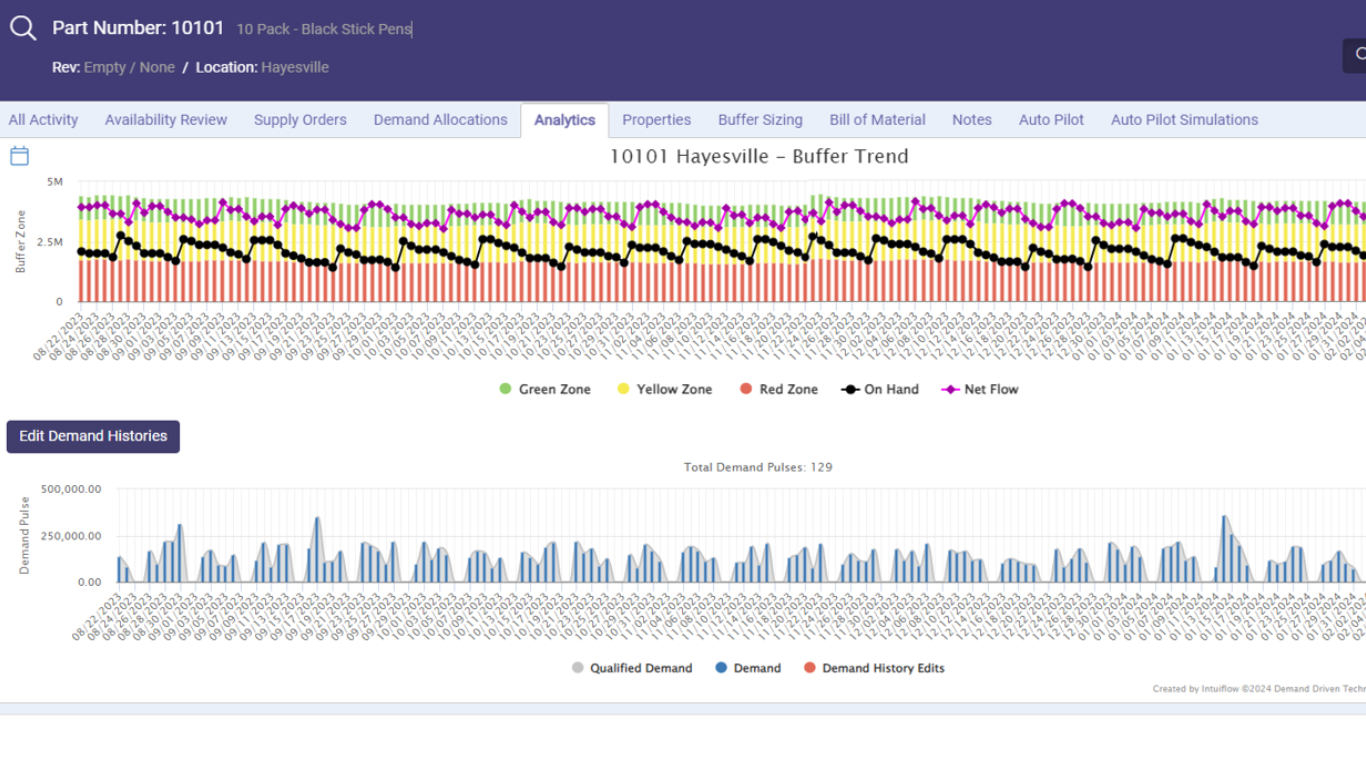

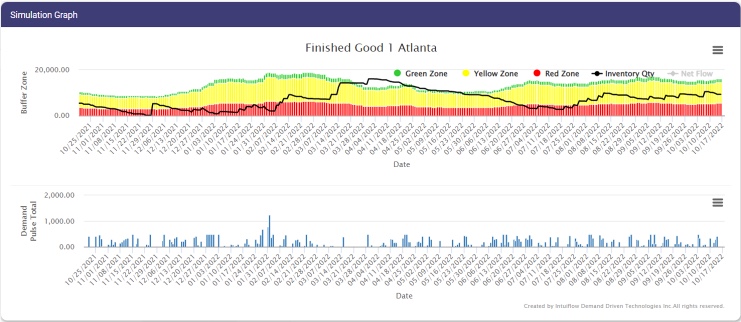

Our team runs your data through our simulation tool.

Results

We get you the results in under 72 hours and one of our experts walks you through the analysis during a call.

Test Scenarios

Want to know what would happen if there is a lead time or MoQ change? Experiment different scenarios with our team!

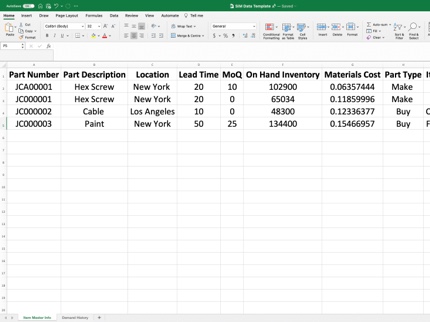

What data do we require?

Master Information

The Master Information tab asks for item master data such as Part number, Lead time, MoQ, and On hand Inventory.

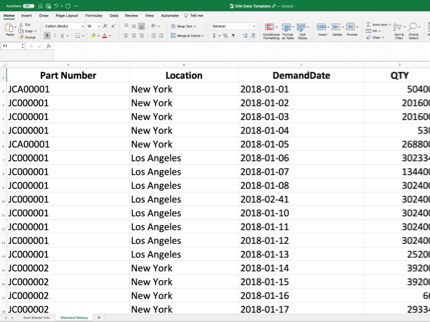

Demand History

The Demand History tab asks for the details of your company’s daily demand.

Ready to see what Intuiflow can do for YOUR business?

John Dilling

CFO

“We have a lot more insight into our inventory control, production planning, and material planning than ever before.”

Steven Wicks

Planning Manager

“If I had to summarize DDMRP into one word it would be visibility. We are able to see, at first glance the actual status of our raw materials and finished goods, which guides us in the right direction to do replenishments in the right order.”

Thibault D’Herouville

VP SUPPLY CHAIN

“The bimodal distribution disappeared very quickly, and the plant planners have an easier way of working.”

Barry Katz

Sr. Director Supply

“We see a competitive advantage for ourselves in the marketplace by being able to deliver very high service levels.”

Scott Faniola

SUPPLY CHAIN DIRECTOR

“Our team used to spend hours a day determining material requirements, lookin g for items, issuing Pos, expediting orders… Now, with Intuiflow, the data is right in front of us first thing in the morning.”

Kyle Keeney

INVENTORY STRATEGY LEAD

“Intuiflow has helped us adapt to changing environments. It enables us to be proactive.”