The S&OP process plays a vital role in how companies function, enabling executives to:

- Forge a strong connection between the two planning horizons: Operational activity and strategy.

- Reconcile and develop a culture of interaction between key departments, including sales, marketing, operations, finance, logistics, and R&D.

- Create an integrated and coordinated plan for the above functions, bringing them toward a common denominator and away from separate plans.

In short, it lays a solid ground for sustainable development and the achievement of key business goals.

Nowadays, new approaches are necessary to sustain competitive advantage in a world that’s changing rapidly — especially when it comes to supply chain.

The traditional S&OP model aims to align supply and demand across a company, bringing together finance, sales, marketing, planning, and other internal functions to reach a plan consensus.

Still, to realize the full potential of S&OP today, companies should mainly focus on customers’ need for satisfaction and demand management, not only on sales and supply balance.

In other words, it’s a requirement to turn demand-driven radars and transform market patterns into effective and profitable company plans.

The traditional S&OP model is a demand-driven process that integrates and coordinates internal operations to make decisions with more transparency, bigger datasets, relevant tools, and insightful analytics. One of the most recent developments in the evolution of S&OP is the Demand Driven S&OP process.

Introducing the DDS&OP Process

The Demand Driven Institute defines DDS&OP as a process of bi-directional tactical reconciliation in the Demand Driven Adaptive Enterprise (DDAE) model between the strategic and operational relevant ranges of decision making.

On the one hand, DDS&OP establishes key operating model parameters based on strategic information (obtained from the Adaptive S&OP process). On the other hand, it uses variance analysis based on past performance and critical indicators (reliability, stability, and speed) to adapt key operating model parameters and/or recommend strategic business changes.

The authors of the DDMRP methodology name the following features of the DDS&OP process as compared to other S&OP models:

- Strategy and capacities alignment

- The use of a dynamic Demand Driven Operating Model

- Bi-directional impact on strategy

- The direction of the process through the relevant ranges.

The Principles of DDS&OP

Let’s point out some principles that the DD S&OP process practices:

1. The tactical reconciliation process is supposed to be continuous, interactive, two-way, and bi-directional

This principle should eliminate situations when the strategy descends and cascades down from the top level, ignoring executive-level feedback and up-to-date information about market signals, as well as when operating plans do not correlate with the company’s global business goals.

The approach implies that the strategy considers the existing limitations and operational capabilities of the operating model. The operating model, in turn, should be configured to meet strategic expectations.

Tactical reconciliation is a constant iterative process with the feedback loops, variance analysis and current model adjustments.

Prior to the strategy adoption, its digitized indicators (sales plan, new product launches, promotions plan, and performance targets) should be estimated and verified in terms of viability: By the investment into inventory, the load on existing capacity or storage facilities, and the level of supply the company will face. Based on the results obtained, the strategy is reviewed or adopted. Afterwards, the operating model is configured.

However, as soon as an actual demand arises, which is the model engine, it enables you to register deviations from expectations in real time, adjust to the operating model, or introduce suggestions that should be escalated and approved at the strategy level.

In fact, it is a combination of strategy, planning, and execution through an iterative process of continuously modeling “what if” scenarios to respond to demand changes.

The operational and strategic levels stand within different relevant ranges. Each of them has its information, assumptions, metrics, and personnel involved. However, without finding a way to align them properly, the company may not see the long-term future that was planned.

2. “Neighbors” involvement within the supply chain processes

The integration with your partners (both suppliers of goods or raw materials for your company and your distributor, or retail chain customers) in the context of transparent inventory management, joint forecast preparation or plans synchronization.

Let’s review a tool of Intuiflow in the tactical planning module as an example that can be applied within this principle.

- This is a report that builds a model of your company’s future supplies (according to the DDMRP methodology) in the mid-term period (up to 15 years) based on sales forecast data by SKU / location.

- This report can be shared with your suppliers to provide an overview of the projected level of shipments they are expected to supply, monitor, and adapt to changes promptly.

- Your suppliers can use this data in their planning processes to improve the level of service, quality, and reliability of their deliveries.

Your clients can help you in the same way. Particularly, if a spike order due to a client’s promotion is expected, the sooner this information is provided to you, the better opportunity you have to fulfill this order in a comfortable way (and time) for everyone.

In fact, because of this principle, the entire supply chain becomes more transparent and predictable, the whip effect is mitigated, and distortions in the information flow are reduced. Each process player analyzes the risks and opportunities that can be implemented and capitalized.

The ability to share information in real time gives supply chain participants the possibility to respond quickly and efficiently to unexpected changes.

The principle of an information boomerang is to share information and it returns to you with the higher level of service!

3. Managing the ranges and possible scenarios, not ultimate figures

Don’t say “10”, say “from 7 to 13” and increase your chances of being right.

The traditional MRP planning approach is based on using one specific accurate number as input, which is then used in the MPS and goes down all the links of supply chain or through the bill of material.

This number is obviously wrong, because a 100% forecast does not exist. When this number is reviewed and updated as part of the monthly S&OP planning, it leads to massive changes in all lower-level components. The process is more like a painful restructuring than sustainable management.

However, an effective S&OP should be based not on discrete numbers, but on projected ranges.

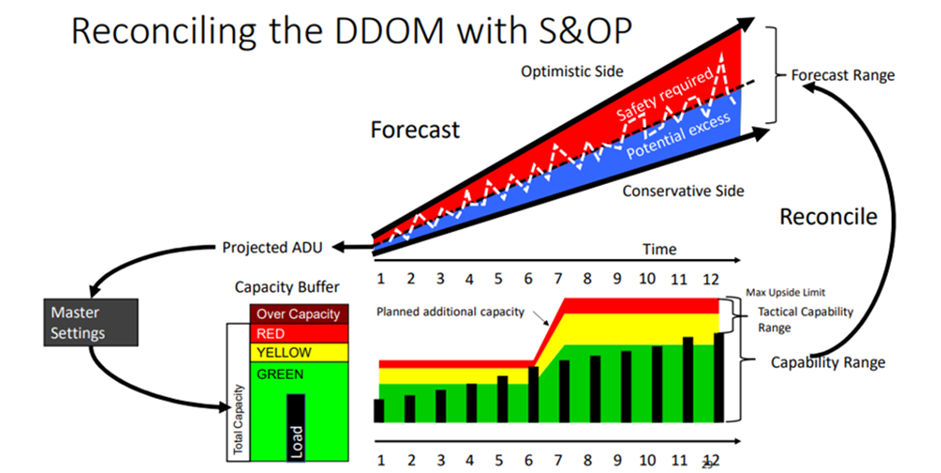

DDS&OP does not utilize MPS. The “Master data” is used to set up and reconfigure the operating model. The main parameters are buffer profiles (strategies for managing groups of SKUs) and average daily usage. The last one is a definite number and can be determined within the Adaptive S&OP, but due to the profile usage, it is transformed into a range of operational capability.

Source: Demand Driven Adaptive Enterprise Webinar, DDI website

- Average daily usage and buffer profile determine the size of the buffer significantly.

- The buffer itself has protective mechanisms — if demand decreases suddenly and the net flow remains in the green zone, the buffer will not be replenished.

- A significant increase in demand should be handled by the red zone, which is designed to mitigate variability.

Numbers would be wrong and vary within a range, but the range would be approximately correct.

If we understand that the range is not enough to cover the variability and error in determining the average daily usage, the range should be expanded by switching between buffer profiles.

The above principles allow you to increase the S&OP process effectiveness and adapt it to current conditions and reality.

It is also important to point out that to perform DDS&OP a Demand Driven Operating Model (DDOM) should exist, at least partly.

In addition, the integration of DDS&OP in the company’s processes is not the final destination, but a step on the evolutionary path of the organization development and transformation to the Demand Driven Adaptive Enterprise (DDAE) model, which makes the company be flexible and easily adaptable to changes in the environment, introduce innovations for continuous profitability improvement and flow protection.