In a factory, the relationship between Supply Chain and Quality teams can be tumultuous…

Quality hold manufacturing batches – put on hold for inspection or rework – queues on key test equipment, release times, all this generates waiting, delays, when we are already in a hurry…

Everyone agrees we must ensure that we deliver defect-free products to customers, and the veto right of the Quality teams is sacred. Nevertheless, it’s annoying to wait for a hypothetical release of a batch when the customer is putting pressure on you to be delivered.

You have experienced this feeling yourself. You must take a plane, the end of the boarding time is approaching, you have just arrived at the airport because of the traffic jams, and there is an interminable queue at the security checkpoint.

You find these security checks quite justified because you want to be safe on the plane, but that doesn’t stop you from complaining. Why is there such a long queue? Don’t they know how to adjust the screening capacity? My flight is imminent, why can’t I go before the others whose flight is in an hour?

Innocents, suspects, and culprits

There are quality batches and quality batches.

Presumed innocent batches

We have just received or manufactured a batch of product, it is likely to be good. We must wait for it to be released, but that batch is presumed innocent – we rely on those quantities to keep the manufacturing or delivery flow going.

Suspect lots

We have just held a batch and put it aside because one of the measurements made established a doubt. It is necessary to check, to re-check, perhaps to sort and to discard a part, perhaps to reprocess, perhaps… In short, it is suspect. Very often these batches enter a purgatory from which we don’t know well when they will come out.

The guilty lots

There is a proven problem, it’s direct to prison!

It is not uncommon for these testing, control, and release processes to take precedence over product lead times – for example in pharma.

In any case, for the planner there is the stress of uncertainty, of waiting, of foreseeing plan B if things go wrong – and a dull resentment that rises: “But what is Quality doing?”…

What if we tried to pacify the relationship between our Supply Chain and Quality teams?

Establish visibility

The quality batches are not always visible.

About twenty years ago, I was working in a plant of a tier-one automotive supplier manufacturing large sub-assemblies, and we had taken a radical decision to foster fast processing of suspect batches: the Quality area had been set up at the entrance of the workshop – in full view of all visitors and the management team. It could not be missed. I can assure you that the suspect batches were quickly declared guilty or innocent!

This physical visibility is not always possible or meaningful. I remember a micro-precision company where the inspection queue consisted of a few small, unimpressive shelves. However, dipping your hand into the back of a shelf it was common to find a bag of parts that had been waiting there for months…

The prerequisite to ensure decision-making is that the quality batches and the queues are visible. “No problem, we have the list in Excel” is not the right answer…

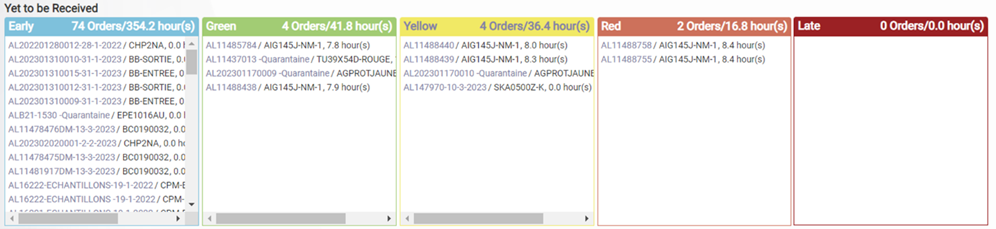

The time buffer view below provides shared visibility between Quality, Supply Chain, and Production teams – and encourages decision-making before falling into the dark red/late box. With such visibility, it becomes easy to animate piloting rituals to arbitrate contentious cases and ensure governance of the release management process.

Note that in this case an inspection routing has been established, which allows the QC/QA team to have an evaluation of the workload to process future lots.

Visibility is for decision making

Confirm in time that the presumed innocent batches are OK – which requires an adapted processing capacity.

Declare suspects guilty or innocent as quickly as possible. It is not a question of establishing expeditious justice, but of investigating cases quickly – which requires an appropriate investigative capacity – and arbitration processes.

Destroy to repair the guilty lots (no, we don’t keep “just in case”).

Think flow rather than stock

In most ERP systems, quality batches are represented as stock, with a lock status. This status is different for culprits (excluded from the MRP calculation) or for presumed innocents (included as resources in the MRP calculation). Suspects can have a variable status depending on the severity of their crime…

Representing these lots as inventory is not the best view, as inventory is static. We recommend representing these batches as open orders – with a due date. This allows us to ask ourselves what actions need to be taken to release a suspicious batch and to plan these actions. It also allows for execution alerts: this batch is scheduled for release next Thursday, but I have a requirement on Tuesday – can it be processed before then, or should I delay delivery and inform the customer?

Aligning teams to ensure flow

Having common visibility, managing priorities in coherence, adjusting capacities to maintain queues at a level compatible with demand, and making decisions: Intuiflow can help you equip the process with the right tools, but the key is in the animation of the teams and in the governance of the cross-functional teams involved!