Quantum physics teaches us that an isolated particle has no property in itself. A particle exists only through the interactions it has with other particles. It is the interactions that constitute matter. Within the broader universe, it is the interactions that make, for example, the earth turn around the sun, the moon around the earth, and our oceans evolve according to the tides.

This universal law, from the infinitely small to the infinitely large, also applies to our supply chains. Interactions are at the heart of a supply chain, and it is the quality of these interactions, from one end of the chain to the other, that determines the performance of our organizations — their ability to respond to demand, react to crises, adapt, and reduce costs and capital requirements.

This preponderance of interactions — of relationships between different internal and external players — is problematic, because it is what prevents us from translating our supply chains into equations. We cannot apply a superb mathematical formula or model our supply chain structure in finite elements to optimize its resistance under stress. Mathematically optimizing a supply chain is a lure. Don’t buy the software that would promise that!

In fact, the situation is even worse, as the Lean and Theory of Constraints approaches rightly point out. When we try to optimize one step in the chain, we often risk deteriorating the system as a whole. Think of the difficulty of optimizing transport lot sizes or minimum order quantities — or reducing the number of changeovers to increase the productivity of a production stage.

Optimizing Supply Chain Interactions

If you have experience in operations, you know that your team spends the most energy on the interfaces between customers and suppliers — and on the boundaries between functions and sectors of your company.

A company is organized into functions, which pursue specific objectives. A supply chain integrates suppliers, subcontractors, and different manufacturing and distribution sites, each of which also pursues its own objectives.

So how do you ensure that the objectives of each actor and each stakeholder in your supply chain are coherent enough to optimize your overall system? How can you break down the silo mentality?

1. Establish a Common Language

A common language can facilitate alignment and provide a holistic vision among disparate actors who are driven by their own objectives. This is what schools of thought and improvement methodologies offer. For example, the gradual spread of Lean methods over the last few decades have brought teams from various companies and functions a common understanding of basic principles. This is also what the Demand Driven Institute’s training courses provide: a shared understanding of a management model and operating principles. It’s a common language within a company but also between companies.

It’s also a common language and basic principles that APICS has been spreading since the 70’s: S&OP/MPS/MRP. Every company knows this today… and has to unlearn some of it that is no longer adapted to our time!

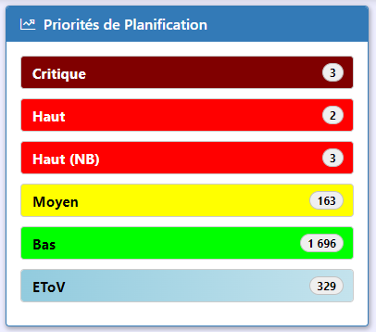

We are not there yet, but we can dream that the standard of stock sizing and replenishment, for all companies, will be in a not-so-distant future based on red, yellow, and green zones, and that each supplier will understand that its red zone, and thus its investment in stock, is intimately linked to the green zone of its customer, i.e., the minimum or the frequency of order.

It is a bit of a dream, but not that much: these behaviors are now common in the multi-site groups that have deployed DDMRP and are beginning to be observed between customers and suppliers who are trained in the methodology.

2. Share Visibility

The second key factor for optimizing interfaces between players is to create visibility. Visibility and transparency induce trust, and thus increase the speed with which relevant and coherent decisions are made.

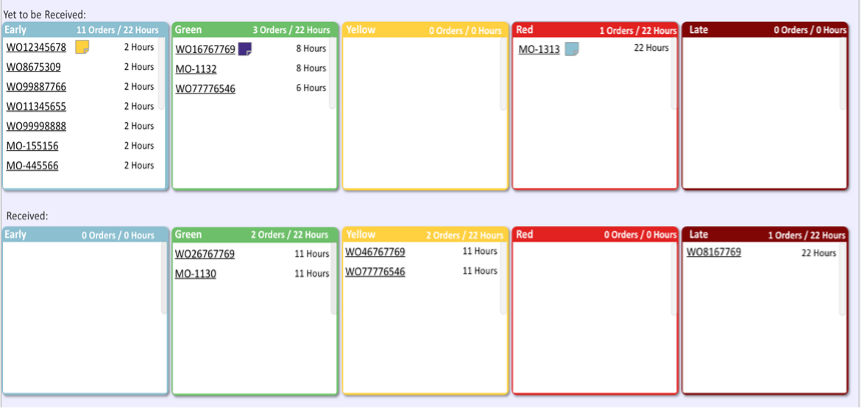

If suppliers and customers share the following vision, there is no ambiguity about what a priority is and why, or what can be deferred:

In a workshop, if the standing meeting is held in front of the buffer board below, everyone agrees on the priorities and the lead/lag status from the start.

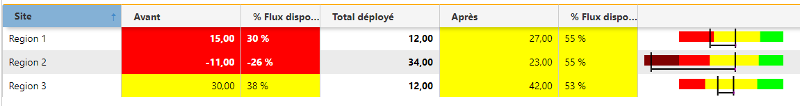

In distribution, there is no ambiguity about which distribution centers or stores have the highest priority.

By enabling this transparency across the chain, Demand Driven tactics and a shared cloud platform build trust and, wherever possible, enable companies to delegate the management of priorities to the upstream link for full accountability and the timely allocation of available resources.

3. Orchestrate Meeting Points

Our supply chains are driven by humans, who are social beings. To understand each other, we need to meet and exchange, not just in a structured way and through software.

From the shop floor standing meeting to the weekly review with key suppliers, from S&OP to the quarterly performance and improvement review, it is essential to orchestrate rituals to unite internal and external teams.

These meeting points allow the formal operating model to be enriched with informal information, to create links between the participants, and to fuel the continuous improvement process. This is the least technical step… but one of the most important.

Transforming together

The projects we support demonstrate this every day: the implementation phase of the Demand Driven model is a powerful team-builder.

It is an opportunity to define a common model across all sites of the company, to set up a common language for the various functions that are involved, to step back, to ask the right questions, to implement a new organization quickly, and to adjust it to the realities of each company.

Breaking down silos is not so complicated: a common methodology, unifying tools for shared visibility, a well-orchestrated transformation, and a lot of leadership — it’s up to you!