DBR+

“The simplicity and ease with which it made the planning process really helped the team get into it from the beginning. If I had to summarize DDMRP into one word it would be visibility.”

~Steven Wicks, Planning Manager – Coca Cola Beverages Africa, Namibia

PRODUCTION PLANNING & SCHEDULING SOFTWARE

MODEL, SCHEDULE and EXECUTE to Market Demand

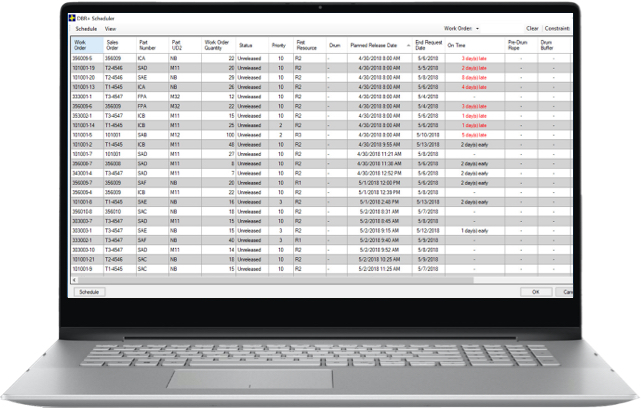

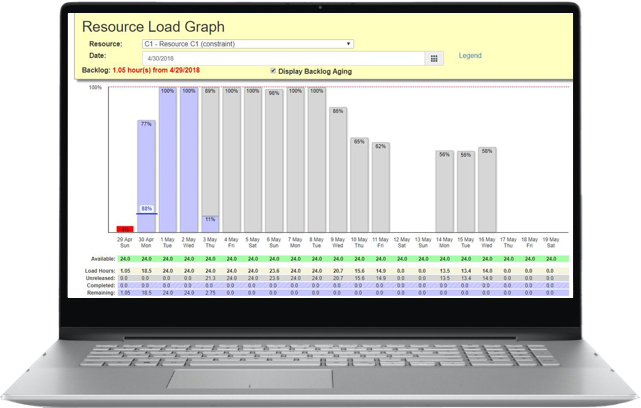

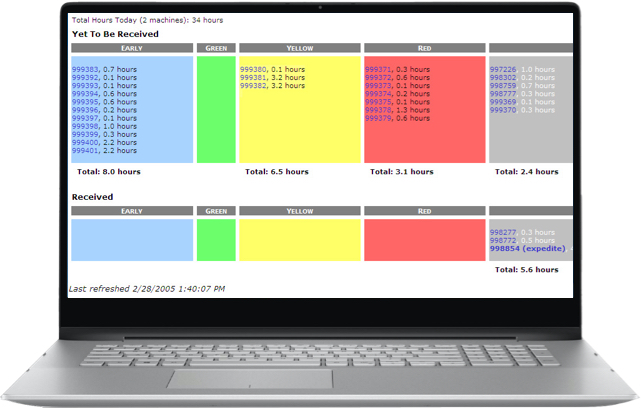

Customer tolerance times are at an all-time low in today’s market driven environment. Conventional production planning software, scheduling and execution techniques and systems are just not good enough to ensure high service levels. With DBR+, you can now align materials and production resources to true market demand, maximizing customer service and throughput performance. Effective use of Capacity and Time buffers dramatically improves due date performance while reducing the impact of variation with resulting improvements to operations stability and productivity.

Increase productivity

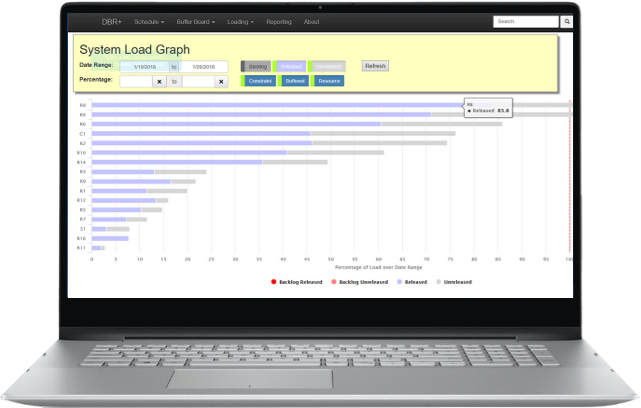

Model and Synchronize resources

Gain insight into backlogs

Improve operational Stability

Ready to see our products in action?

Latest Insights from Demand Driven Technologies

Are internal suppliers good suppliers? A few years ago, I had just joined a renowned international high-tech company as Supply Chain Director. I’d come from an automotive supplier, where I’d...

Will you succumb to the new glamour? Despite decades of new practices and increasingly powerful IT systems, are you still mired in shortages, emergencies, excess stock and a plethora of...

Compare the best DDS&OP software of 2025. See features, compliance & choose the right demand‑driven S&OP platform for your organization.

The merry-go-round In thirty years of responsibilities in major industrial groups and ten years as a consultant, I’ve seen a lot of managerial changes! That said, I understand – I...

The traditional division of labor In the supply chain organizations of large companies, work is divided between teams of demand planners and supply planners. Demand planners interact with sales and...

Variability, the enemy of flow As any supply chain practitioner knows, variability is deleterious – variability runs against our ability to have the right product in the right place at...