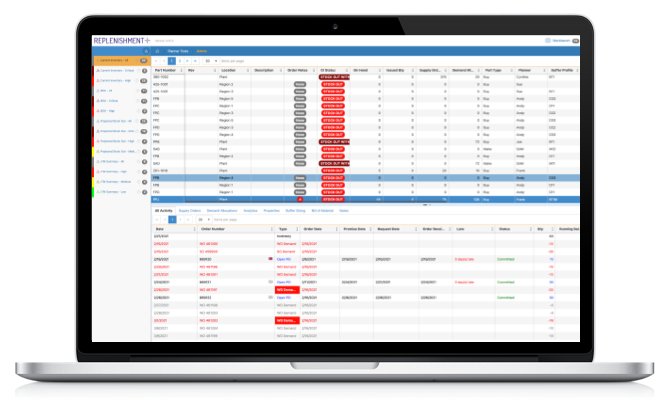

Replenishment+ MRP Software

~Bruce Janowsky , CEO - Jamestown Container Companies

DEMAND DRIVEN MRP SOFTWARE

Faster Alignment, Better Performance

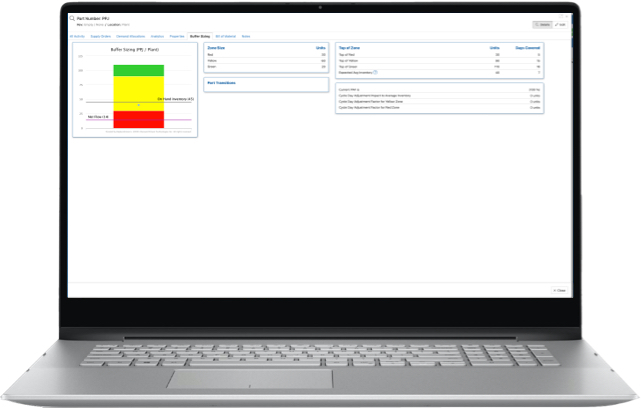

Replenishment+ is the industry’s leading demand driven MRP software, designed to dramatically improve material requirements planning by shifting from forecasts to sales order driven planning — enabling you to improve service levels and make smarter, faster decisions. Based on Demand Driven MRP (DDMRP) principles, it automatically identifies strategic inventory positions so you can know sooner and act faster when supply and demand are misaligned. Thanks to its built-in execution and analytics suite, it also simplifies planning and focuses executive attention on what really matters. Replenishment+ is the first fully compliant materials planning solution to be certified by the Demand Driven Institute.

Integration is easy. Replenishment+ integrates with all major ERP systems, including SAP, Sage, Microsoft Dynamics, Infor, and more. We also offer a NetSuite native MRP software solution.

Enhance Service Levels

Optimize inventory

free up working capital

shorten lead times

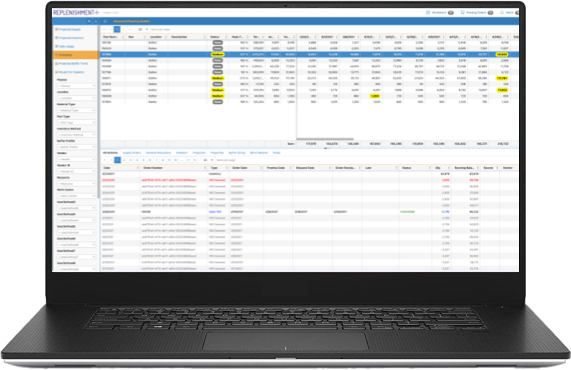

Streamline S&OP with the Replenishment+ Advanced Planning Module

The Replenishment+ Advanced Planning Module (APM) provides deeper insight into long-range resource planning for even greater operational stability. This add-on S&OP software module powers improvements in inventory position, service levels, and lead times by helping you evaluate potential scenarios and adjust the operations that are most at risk.

The Power of Demand Driven Materials Requirements Planning

- Protect against severe fluctuations and stock outs

- Easily plan for anticipated adjustments like seasonal spikes

- Increase working capital by reducing procured materials and idle inventory

- Eliminate the guesswork caused by inaccurate forecasts—and make decisions based on real sales orders.

- Replace disconnected spreadsheets while providing end-to-end visibility.

- Monitor and manage material planning across multiple locations