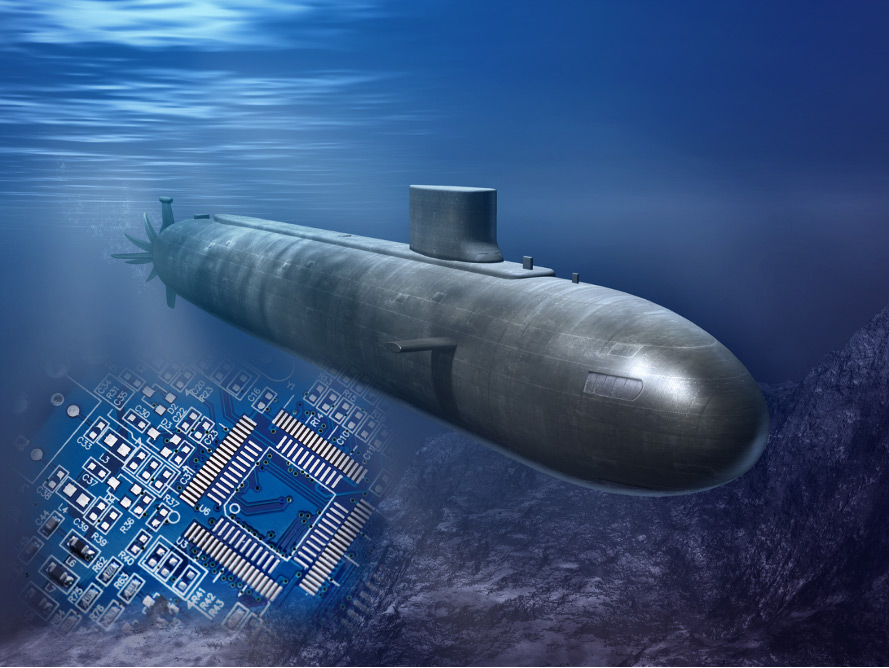

What is the relationship between submarines and the global supply chain?

Don’t worry, it doesn’t have to do with underwater container ships, and Elon Musk hasn’t floated the idea of a silk road via an underwater Hyperloop. Well, not yet, I guess.

But what is it about?

We have recently seen in the press the announcement of the so-called Aukus agreement, signed by the United States, the UK, and Australia. Aukus is a security agreement, and its consequences concerning the supply of nuclear submarines to Australia have caused a diplomatic crisis with France.

However, the agreement focuses on China. Aukus aims to counterbalance China’s expansion in Asia and limit the power of its supply chain, particularly in high technology. China has developed into an unrivalled economic power, coupled with a military power — in particular with a navy that now exceeds the US Navy.

The pandemic has brought into sharp relief the dependence of global supply chains and entire sectors of global industry on China. We have seen this with medical devices, with active pharmaceutical ingredients, and finally with semiconductors.

I spent a good part of my career in the electronics industry in Europe — notably at Philips and Motorola — and I had the opportunity to observe some of the fundamental movements that led to the virtual disappearance of this industry in the West.

There has never been any doubt over the last few decades that electronics and digital devices would become more and more important in our daily lives, and therefore in the industry. Computers, phones, and even cars — the electronic content in a vehicle has exploded over the years, with multiple ECUs, ubiquitous infotainment, semi-autonomous driving, etc.

All this was foreseeable, and therefore anticipable, had the individual players in the industry acted in a concerted, strategic, and geopolitical manner with the states or economic zones in which they operate.

Unfortunately, this is not how it works, or at least how it has worked for the last few decades. Every manufacturer is in competition, and will look for a lower unit cost supply in the short term to support the launch of their products. The basic dynamics of globalized capitalism have led to the same result in Europe and North America: the electronics industry has been decimated, to the benefit of Asia.

Who remembers Serge Tchuruk, then CEO of Alcatel, boasting in 2001 of becoming “Fabless” and announcing the closure of all its factories? Who, for that matter, remembers Alcatel, which in 2005 was present in 130 countries and had a turnover of 13 billion Euros?

The Risks of a Cost-First Strategy

That this creates fragilities in the supply chain, costs and risks, longer lead times and shortages, was obviously not part of the short-term equation for industrial and political leaders of the time. Cost first, flow, uh flow, what are you talking about?

For example, according to an article in The Conversation at the end of 2019, global production capacity was equivalent to 19.4 million wafers — units of the semiconductor material that’s used to make electronics components. European production capacity was, at that time, only 1.1 million wafers. That of the United States was 2.4 million. Since 2019 the imbalance has continued to grow in favor of Asia.

In the West, however, we had some of the best semiconductor companies in the 90s. In 2019, Europe’s STMicroelectronics, Infineon and NXP (formerly Philips Semiconductors and Motorola SPS) were only the 12th, 13th and 14th largest semiconductor companies. In the US, semiconductor manufacturing capacity used to account for 37% of global capacity in the 90s. It has dropped to 12% today.

The biggest foundry in the world is now TSMC, the Taiwanese giant that supplies NVidia, Qualcomm and Apple wafers, amongst others. It has 50% of the market for foundry services. Taiwan, China, development of the Chinese navy, military maneuvers, submarines… do you see a connection?

In 2020 the United States established the “CHIPS for America Act” aimed at relocating this strategic industry, Europe followed suit with the European Chips Act, aiming to establish 20% of the world’s capacity in Europe by 2030.

We can be happy with these initiatives, and dream of shorter, less fragile, more agile supply chains, with capacity buffers in place.

In the meantime, many industries using electronic components will have to face shortages and long lead times and must balance their stocks and supplies with demand as best they can, because there is nothing worse in a scarcity situation than ordering items that you don’t really need and generating bullwhip effects in your supply chain.

Flow before cost, dampened bullwhip effect, timely capacity development… wish that industry had been more demand driven.