Orchestrating the launch of new products is one of the processes you need to define when designing your Demand Driven model.

It uses special techniques for several reasons:

- Since this is a new product, you have no historical demand

- The uncertainty on the demand profile is greater than for a mature product

- There can be initial phenomena: filling a distribution network, quantities for training, quantities for display in stores…

When launching a new product, risks will have to be taken. However, the objective is to take fewer risks than in conventional planning techniques.

Often, in the conventional approach, under pressure from legitimately optimistic marketing and sales teams, an initial “push” will be orchestrated – sourcing or buying a large initial quantity and pushing it down the distribution network for maximum initial availability close to customers. This tactic has its drawbacks: on how many launches does the initial quantity turn out to be too large, and the inventory deployed to the wrong destinations?

The objective is to adopt tactics that will allow a progressive adaptation to the reality of the demand, with replenishments as the demand materializes.

How to Calculate the Average Daily Usage (ADU)

You do not have a history of new items, so you must base your ADU on some form of forecast.

If you do not have a forecasting process, you can set one up for your new items, at least via Excel (hum…), and switch the calculation of these items to the average daily forecast. If you have a forecasting solution (for example, the one from our partner Colibri), it is even better because you have a calculation base that has been subject to a collaborative process involving marketing, sales and supply chain.

You can also link these new items to existing items, through the supersession features, to retrieve their history and possibly apply an increase or decrease factor to them.

The last option is to position a static ADU to start the flow.

In any case, special monitoring will be required from the moment the actual demand materializes, to adapt the profile and transition to “series production” mode as soon as there is enough maturity.

Which Buffer Profile?

If you think your new articles should look like existing items, you can associate the profiles of these source items with your new articles.

You can also define buffer profiles dedicated to your new products. For example, a “New Product, Average Delay, Average Variability” profile. These profiles will be assigned by default to all new products, until you have enough time to assign standard or automatic profiles with our “Smart Buffer Profiler” wizard.

The third option is to temporarily set a static profile (Replenished Override or Min/Max).

Whichever option you choose, we recommend for new products:

- Reduce the green zone as much as possible. In this phase it is more critical to get the right product to the right place with frequent replenishment rather than to be productive.

- Secure the red zone. You are bound to have more uncertainty. A good practice is to temporarily apply a red zone adjustment factor to your affected items.

Project Scenarios and Position Adjustment Factors Accordingly

The use of the DDS&OP module (Advanced Planning Module) allows you to test possible demand scenarios, including the initial phenomena of multilevel inventory start-up, and to pre-position buffer adjustments to meet them.

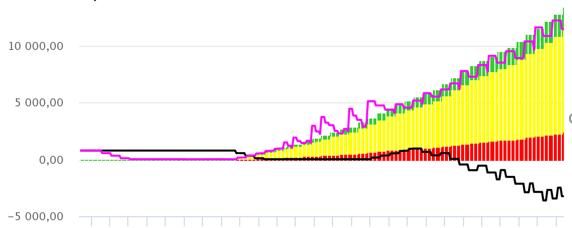

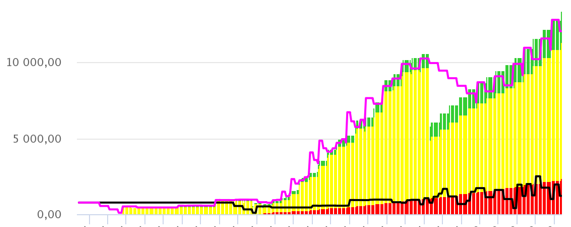

The example below, taken from a real customer scenario, shows the projection of a buffer on a fast ramp-up scenario. It is clear that the buffer would not respond in time.

The application of the proposed yellow zone adjustment factors establishes a viable scenario, with anticipated manufacturing. This scenario will be updated as the project is progresses, and will allow you to adapt capacities through the RCCP process.

Take Care, New Products are the Future of the Company!

Successful product launches are key, as future sustainability and revenues are directly linked to these successes. From Adaptive S&OP to replenishment tactics, the Demand Driven Adaptive Enterprise model provides a process to better adapt product launches to real market demand, and limits the risks associated with flow tactics based on forecasts that are necessarily worse than ever at the time of a launch…