When you learn the principles of MRP, you use a view like the one below.

| Periods | 1 | 2 | 3 | 4 | 5 | 6 | |

| Forecast | 40 | 50 | 40 | 40 | 70 | 20 | |

| Registered orders | 80 | 45 | 30 | 50 | 50 | 5 | |

| Requirements | 80 | 45 | 40 | 50 | 70 | 20 | |

| Projected Inventory | 50 | 170 | 125 | 85 | 35 | 165 | 145 |

| Procurement / production | 200 | 200 | |||||

| Available To promise | 45 | 145 |

Depending on the ERP system, the screen will take different forms, but the ingredients remain the same. If, for example, you are a planner in a company that uses SAP, chances are that you spend a good part of your time on the sacrosanct MD04 screen!

This screen is quite logical: we project the needs by period, the available resources by period, and therefore the inventory. According to this projected stock, we trigger supplies, if for example the projected stock falls below the safety stock.

It’s square, rational, and allows us to create the ideal plan for today.

In some just-in-time environments, for example for automotive parts, this view is used very strictly, with a narrow window, so that the stock never goes too low (e.g. to less than 3 days of need), nor too high (e.g. to more than 7 days of need).

This is a formal view, from the company’s ERP system of record, so the numbers are official and authoritative… At least for today!

The Trouble With Projected Inventory

Unfortunately, as any planner is aware, tomorrow’s view may not tell the same story anymore… And yesterday’s ideal plan may ultimately lead to a risk of shortage on one item, while the item next to it is overstocked!

How is this possible, when the initial reasoning is perfectly logical? Why not trust the MD04 screen?

In fact, the projected stock is this: a projection, i.e. an assumption. Don’t kid yourself, the projected stock will not happen!

All figures represented in the table above are estimates. Sales forecasts are estimates. Orders booked may change: some will be delayed, others will drop in. Supplies and production may not arrive exactly when expected, some will be ahead, some will be delayed, or there may be a quality issue.

You have to be aware of this: the projected inventory is an illusion. The reality will be different. Do not think that your MD04 screen or the MRP workbench of your ERP is telling you the truth — even if it has all the signs of legitimacy with its precise figures and dates!

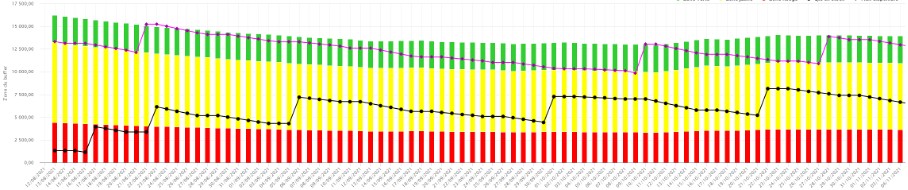

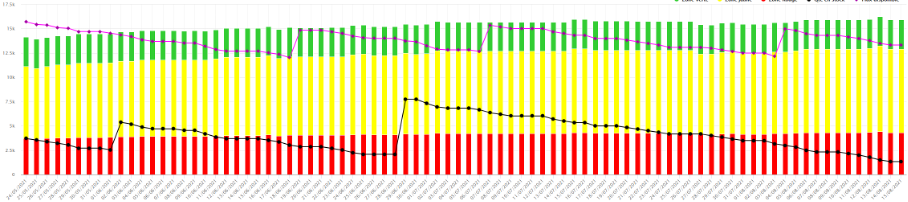

The same is true with the inventory projections you can make with DDMRP as part of the DDS&OP process. The view below for the next few weeks will probably not come out exactly the same.

You only have to look at the below chart of the past weeks to see that what has happened is different from what was expected. For example, you should have received goods every 3 to 4 weeks, but we have not received anything for two months and your stock is getting dangerously low. You plan to receive two shipments in the next two weeks. That’s what your supplier says, but will they be there in time?

Relying on a projected stock view sounds very logical, but in fact it is dangerous:

- If we rely on the projection, we will supply just what is needed. By doing this, we generally create instability, because we base everything on the precise, but illusory, data set of the days/weeks to come. When we determine the need for replenishment with a DDMRP buffer, we base our decision on an AVERAGE consumption or forecast per day which is determined over a smoothing horizon. For example, we will take the average of the forecasts for the next 8 weeks and the consumption of the last 8 weeks. This will allow us to be more relevant in the majority of cases because it will paced by a real background consumption. On the other hand, our favorite MD04 makes us stop and go…

- You end up believing the numbers on the screen and forget that they are just assumptions. The DDS&OP approach is based on taking scenarios into account and identifying by exception those items that are at risk of going too low or too high. Doing so focuses the planners’ attention on these risks, the execution alerts, and the actions to be taken to mitigate the risks.

Moving from a projected stock MRP view to a DDMRP approach based on consumption rates and scenarios is not so simple for planners who have been used to MRP for a long time. MD04 seems to allow for better inventory optimization, while the averaged and exception-based approach of DDMRP can be perceived as less Cartesian. The fact is that we do not live in a Cartesian environment, but in a fluid and changing environment.

Practice shows that when you take the plunge you get much better results in terms of service and stock. You just have to be willing to let go…