We sometimes arrive at Supply Chain jobs in a roundabout way. Initial training in Supply Chain has developed over the last few years, but very often the actors of the supply chain teams – planners, managers, or directors – have different initial training.

In these teams, we find defectors from production, purchasing, foreign language specialists, finance, or even, like me, lost electronics engineers…

The plurality of profiles is a richness for the Supply Chain team – it facilitates the interaction with the other functions of the company – if you have production experience you are more legitimate and relevant to put some pressure on your partners in the workshop, and to find solutions with them.

The downside is that there may be a lack of technical knowledge about the best supply chain practices to implement. In some companies, the supply chain is thought to be just common sense – so if you have common sense and a little desire to deal with the stress of everyday life, come and join us!

I did this at the beginning of my career: coming from a technical background, I found myself doing supply chain in my first factory, without any other theoretical background. I tried to learn from my peers and to read a little, but frankly, with hindsight, I fumbled a lot and made some big mistakes.

After four years of practice, I was lucky enough that my employer at the time enrolled me in a certification course, the CPIM of APICS (now ASCM). The training was demanding, and very rich, but brought me a lot:

- A common vocabulary, which facilitated interactions with other teams and sites in the company,

- Knowledge sharing and benchmarking with other training participants: “How do you do your S&OP?”

- More confidence in my operational practice, following a recognized framework – the MRP2 model

I then put it into practice, hit a few roadblocks, learned the smoothed pull flow techniques in addition – and have continued to learn over 35 years of practice. Beyond the original CPIM, I had the opportunity to pass the CIRM (now defunct), to follow the Black Belt Lean 6 Sigma course, as well as the certifications of the Demand Driven Institute, of which I am a trainer.

The contribution of these pieces of training for me has been undeniable. The fact that I had to pass the certification is also key – not because of the recognition it brings with a badge on LinkedIn, but because it forced me to work, to dig into the subject, and to ask myself questions.

I can only encourage you to get out of your operational urgencies and take a step back through education because it is the adaptation of methodologies that allows for process improvement and the delivery of operational results.

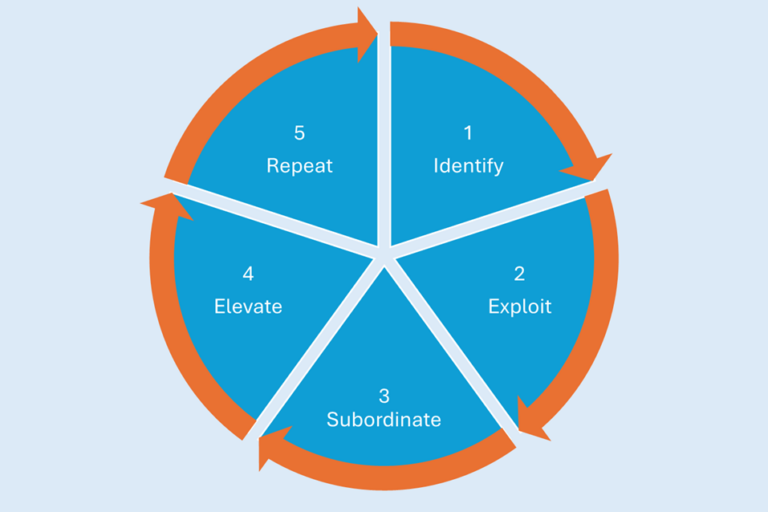

The difficulty you may encounter is that supply chain certification training products have proliferated in recent years. What’s more, these courses often refer to a school of thought. We should do it this way and not that way. MRP, Lean 6 Sigma, Theory of Constraints, Demand Driven – so many schools of thought that sometimes border on belief, and which have their supporters and detractors. Formats have also evolved, with online offerings without physical meetings.

Recommendations to guide you in selecting training content and enriching your course:

- Whatever the training you follow, exercise your critical sense, the first quality in the supply chain (in addition to common sense, of course)

- You need to know the fundamentals of MRP, simply because it is at the heart of current ERP systems, and current practices in many companies. Like many, I think that MRP has never been sufficient and is more and more inadequate, but to make it evolve, you have to know it well.

- Learn pull flow techniques – Lean, TOC, and of course, the Demand Driven Institute content. Do it via courses, books, games, experimentation, and operational practice. There is a lot of material available, stands on the shoulders of the giants who have explored these areas, Shigeo Shingo, Taiichi Ohno, Eli Goldratt, John Shook, Carol Ptak, Chad Smith, and others. Do not oppose each other – think “how to blend all this content ?”.

- Select trainers who are pragmatic, who have strong operational experience, and who will not try to sell you a dogma or software.

- If you can, take certifications – it allows you to dig deeper and understand the subject.

- Meet other supply chain practitioners, in other fields than yours. Compare your practices. Use best practice guidelines. Constantly challenge yourself.

- And above all: experiment, learn from your mistakes, keep learning, and encourage experimentation and continuous improvement within your teams. Never be certain: doubt, and keep learning!

There will be a great opportunity for continuing education and various supply chain topics discussion at our upcoming User Conference. The event will take place in Atlanta, GA on May 24th and 25th. This will be both an in-person and virtual event with all sessions live-streamed and recordings available after. Check out the event page and make sure to register for the event! Our French User Conference will be held on June 20th & 21st in Bordeaux, France. Follow us on social media for updates regarding both of our User Conferences.