In our first article on the 4.0 shop floor, we looked at how to start production orders at the right time. Then, we discussed how to optimize production batch size and synchronize manufacturing flows.

In this article, we’ll outline how to use queues to accelerate production flows.

Managing Production Flow

If you have ever participated in value stream mapping (VSM), or been trained in Lean, this concept is familiar to you: most of the time our production flows is spent waiting.

Lean has popularized the concept of flow tension ratio, which is the ratio between the production lead time and the sum of the technological times. It is common to see that more than 99% of the time in our production flows is waiting.

So when you’re in charge of managing production, your attention should be focused on managing wait times, rather than on managing conversion time. Being the “big boss of the queues,” ok, it’s less sexy than production manager or flow manager, and yet…

Driving Wait Times

To pilot, you must see. If you don’t see wait times, how can you drive them?

In this digital age, how do we represent wait times in our control systems? The conventional method, used by most ERP systems, scheduling tools, and MES, is to sprinkle waiting times here and there.

Each time we have a routing operation, we have a queue time before, a setup time, a run time. The intention is commendable: to represent each operation with an allocated lead time that is reasonable, fair, so that each operation can be staked out, and its completion tracked against a realistic schedule.

That’s ok on simple routings, but what if your routings include 10, 30, 100 operations, spread over several load centers common to multiple flows, with perhaps also some subcontracting steps?

In this case, you will sprinkle waiting times over 30 operations, and you will have no visibility on the real consumption of these allocated queue times. So, you will end up engraving them in the marble of your routings and impose these lead times onto your customers. On the other hand, you will have to finely control the 30 operations in relation to their respective milestones — with a few hazards here and there, several workshop managers involved, it will keep the teams busy… Sounds familiar ?

To control the waiting times, we need to represent them in the digital control system.

Establish Leverage Points

To control the queue times, we must first remove them from the routing times. These routings should include only the setup times, run times, and possibly the imposed technical times (cooling, polymerization, drying, etc…)

These routings therefore no longer represent the realistic lead time, the time it takes for our work orders to pass through our production system. This time takes more than run and setup time. There are hazards, variability, that we need to cushion, in orders to protect the flow.

We are therefore going to put these waiting times, removed from the routings, back into certain places in the manufacturing process, which we will use as leverage points. We are going to position them at the end of the flow, to protect the availability to customers, in front of the critical production steps to be protected, and at the points where we are going to control priorities. These are what we call “time buffers.”

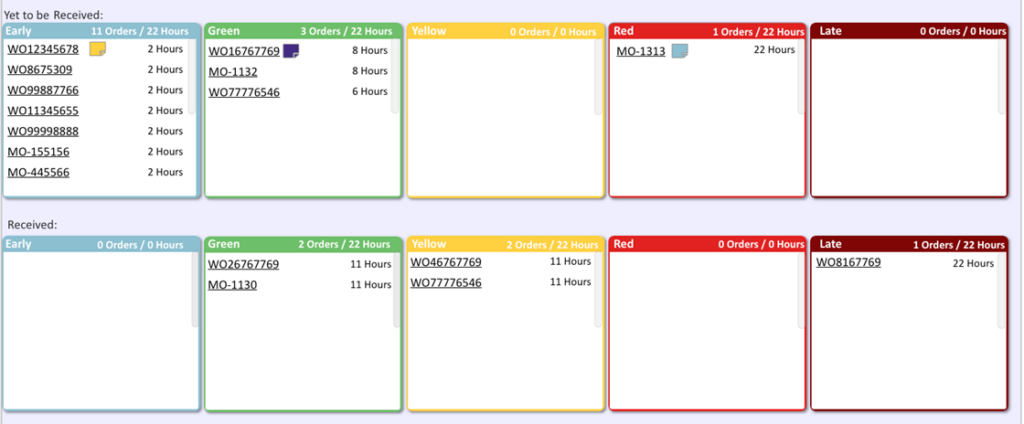

On these operations, we do not put these time buffers back into the routings: we drive them in our Intuiflow or DBR+ solutions, in order to:

- Make these time buffers visible (visualize queues)

- Allow a red/yellow/green priority management on these points

- Measure the consumption of these buffers

- Reduce buffers over time, and thus reduce lead times

Seeing wait times is a prerequisite for driving them down.

These techniques, defined by the Theory of Constraints, are still not widespread. One of the obstacles to their adoption was the lack of digital solutions to implement them: often these time buffers are physical boards or Excel.

But that was before Intuiflow and DBR+ 😉 … and other DDOM Compliant software, as certified by the Demand Driven Institute.

Now, Go Pilot Your Queues

In short, instead of sprinkling waiting times throughout the process, you must pool them in a limited number of points, make them visible, and measure their consumption.

If we want to focus on the value brought to the customers, on the adaptation to their real demand, it is indeed on the 95%+ of waiting time that we must focus. The first step is to make them visible. The second step will be to use them in the management rituals, which we will come back to in a future article.