Welcome to the new normal.

Supply chains felt the turbulence of the pandemic, the container ship, and microchip crises. Now, war in Ukraine and sanctions against Russia are increasing volatility on the global market and reshaping global trade. Our clients across the globe have claimed that average lead time from their overseas suppliers increased by 30% and order fulfillment rate decreased by 6% compared to 2019. We do not know the future, but one thing we can be sure of is that the frequency and range of global challenges will only increase, resulting in growth of uncertainty, complexity, and ambiguity in our supply chains.

Competitive market pressure tends to benefit consumers. They want to receive their goods faster (which shortens lead times), in greater assortment (which increases product variety) and with new features (which leads to more complex and shorter product life cycles) at a reasonable price. However, this last one puts a great pressure on internal processes, efficiency, and cost — and supply chain is no exception.

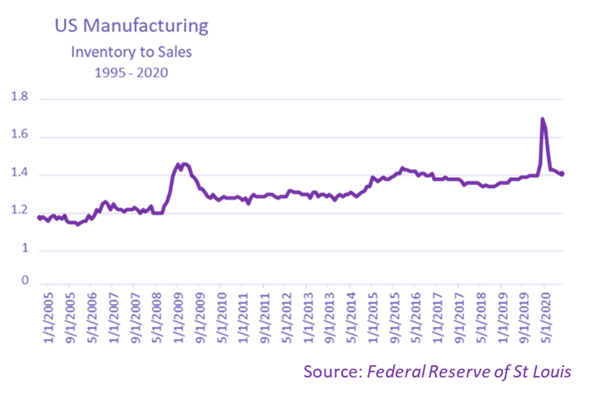

Despite the proliferation of MRP modules in ERP systems and Advanced Planning software, about 80% of companies use Excel Spreadsheets to manage their inventory. They know there’s something wrong with MRP; they don’t trust it, and they work around it. Still, over the years, inventory-to-sales ratios keep deteriorating, with a simultaneous increase of stock outs. This is called bi-modal inventory distribution, when companies are having too little of the right, too much of the wrong and overall, too much stock.

Why is this happening?

Push and Pull Planning Methods

The idea behind Push methods is straightforward: it’s based on forecasts. At the risk of oversimplification, I’ll try to describe the idea. First, you forecast the client’s orders and build a production plan, considering WIP, current inventories, equipment, and so on. When you know how much and when to start to produce, you can easily calculate your requirements for materials by exploding this demand through the Bill of Material (BOM). That is what MRP is all about.

The efficiency of this method highly depends on how reliable your suppliers are, how accurate your master data are, how reliable the production schedule is, and how precisely you can forecast your client’s orders. If any of this is wrong (and we know it is), your production plan will not be able to be executed. This is one of the reasons planners use spreadsheets, because we do not live in a perfect world. There is lots of variability, complexity, and nonlinearity that MRP does not know how to handle.

Many FMCG companies’ safety stock levels depend on forecast accuracy. It seems like common sense: the more precisely you know the future sales, the less extra stock you need to cover them. Unfortunately, past data does not describe the future, no matter how well you research it.

Let’s review the real-life example we discussed earlier. Say everything is going according to the production schedule and you are about to run product “C.” Suddenly, an urgent order for product “F” appears. What should you do? Build “C” and be cost-effective, or break your schedule, and build “F”?

If you build “C,” you’ll get a higher marks on your schedule execution and achieve higher efficiency for the company. As a result, the planner will get a bonus at the end of the month. If you build “F,” the sales department will execute its sales plan and receive a bonus. But your planner will not execute the schedule as planned and will not receive a bonus due to “low operational efficiency.” This is one of the reasons why companies often suffer from conflicts between functions — because success of one will lead to failure of another.

The more stable and predictable the environment in which the company operates, both internally and in product sales, the more efficient Push methods are. The problem is that uncertainty and volatility are only increasing, derogating the efficiency of MRP, and spreading the bi-modal inventory distribution.

Then the Pull methods emerge. Classical examples of Pull methods are Lean and ToC. Again, at the risk of oversimplification, I’ll try to describe the overall idea. Pull methods try to make the system operationally efficient and agile so that companies adjust to market fluctuations, by pulling only what the market requires.

One of the downsides of this approach is a that it ends up limiting agility. In particular, when market fluctuations are directly transferred to the shop floor, without mitigation, it reduces overall efficiency. Unfortunately, Pull methods do not have an efficient connection with S&OP, as MRP does, making them less synchronized with the company’s business plan. For example, in ToC, the past dynamic of your inventory level relative to your current buffer size defines your future stock levels.

Pull methods are reactive by their nature and the more complex and volatile the environment is, the less efficient they are. Therefore, companies go back to MRP after implementing Pull inventory planning methods. The most common market situation I’ve met is companies which use Lean and ToC to increase their operational performance, amp the flow, etc., but plan their inventories by MRP.

DDMRP: The Best of Both Worlds

DDMRP is a new planning method which has strengths of both Push and Pull methods without their weaknesses. The DDMRP buffers depict both the operational environment in the company (lead times, MOQ, frequency of setups, reliability of suppliers, equipment, and so on) and the company’s business plan (strategically defined decoupling points, product portfolio, and sales expectations). This allows planners to easily manage the entire system through the S&OP process, typically close to how they used to with MRP at the beginning, making the transition from MRP to DDMRP quite easy.

But, on an operational level, only actual client’s orders will launch production and purchasing orders. This paces the company’s operations and inventories to actual demand. Thus, the conflict between the functions from the MRP example isn’t even possible because the planner will build what the customer wants, but not what was in the forecast or Master Production Schedule. Sales now can fulfill more customers orders and even create new competitive advantages.

The more complex, volatile, and uncertain the environment, the better the results of DDMRP compared to conventional techniques.

Stay tuned, as in the next article we will compare each of the traditional planning methods with DDMRP and dive into the Demand Driven approach to gain more insights on how to build a sustainable and adaptive supply chain in the VUCA world.