If the forecasts are wrong, what is the point of forecasting?

The subject of forecasting has been stirring the supply chain community for ages. We have invested a lot, and continue to invest in this subject, with a renewed interest in the age of artificial intelligence, machine learning, big data. We are keeping our fingers crossed: perhaps these technologies will help us improve the forecast accuracy?

We are often disappointed: no matter how hard we try to forecast, actual sales are significantly different, especially at the SKU level.

Our product portfolios are increasingly diversified, new products are being introduced at a frantic pace, there are more and more players competing in the market, geopolitical uncertainties are omnipresent, not to mention the pandemic.

So, there is no secret: the forecast accuracy is deteriorating, and will continue to deteriorate, because quite simply the environment in which we operate is becoming less and less predictable.

When DDMRP emerged, there was a lot of debate: since the forecasts are wrong, let’s break our crystal ball, establish buffers based on the average daily consumption of the last few weeks, and everything will be fine. The debate raged in France in 2014. Curiously, it still reappears from time to time, which shows multiple misunderstandings.

I have never agreed with the speech about abandoning forecasts. Quite simply because I have 35 years of experience in the supply chain, and I have seen first-hand the value of pragmatic forecasting processes. I have also lived through extreme situations one way or the other, and learned to be wary of them…

The F*** word or the illusion of “true demand”

I worked years ago in an American medical device group undergoing a Lean transformation, based at the time on the principles of Demand Flow Technology. The leaders of this transformation in the company were fierce opponents of any forecast – “Forecast” was considered in the company as “The F*** word”, to be banished. Everything had to be done based on “true demand”.

One of the US project managers had implemented a pull flow management system for a key plant in Europe. His obsession was not to use forecasts, so he based average daily usage on the sales history of the last three months, which was supposed to represent “real demand”. When sales soared in October – as they do every year – while “true demand” was calculated on July-September, a weak period due to vacations in Europe, what do you think happened?

It took 5 months for the plant, at full capacity, to get back on its feet, and a year for the company to regain the confidence of its customers.

The example seems caricatured, yet it is very real. What was missing within this company? A little less dogmatism and a little more common sense, to feed an S&OP process with relevant aggregated forecasts, and to adjust the kanban loops according to these forecasts on strategic items.

The illusion of detailed forecasts

At the opposite end of the spectrum, many companies make inordinate efforts to produce highly detailed forecasts: by SKU, by customer, by week or even by day.

At a conference, I attended the presentation of a company in the apparel sector that had implemented algorithms on a big data database (we speak in terabytes), to determine forecasts per day and article at store level. But once I know that we should sell 0.00001 units of this T-shirt in size S on Monday in my store, what do I do?

Again, the example is extreme, but if you look at the forecasting process of most companies, it is done at a level far too detailed to be useful. The more detailed a forecast is, the more wrong it is. The more detailed a forecast is, the more effort it requires from your teams of forecasters or demand managers.

A lot of energy for a falsely accurate result from which no relevant decision can be made, let us avoid these waste.

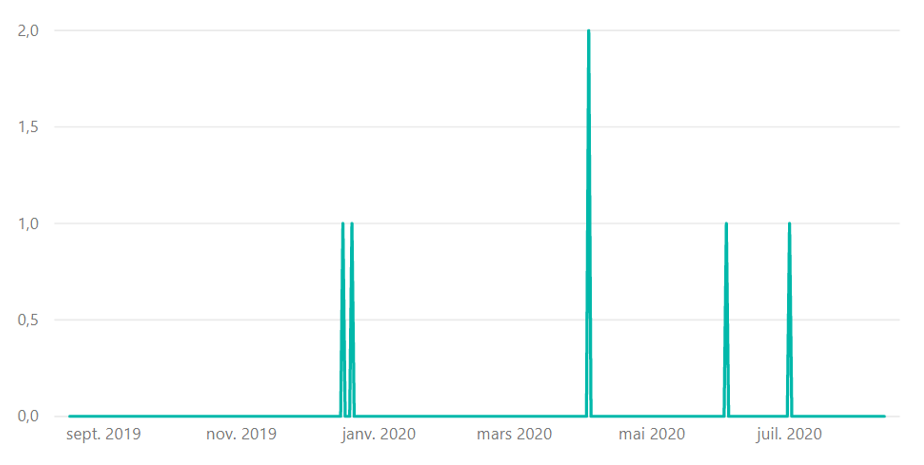

Some items do not deserve a forecasting effort. Let us take the example of the article for which the demand is as follows:

Will a forecast help you process this article?

Either you forecast a sale of 0.02 per day or 0.6 per month, or 1 every x month and you are likely to position this forecast on the wrong month – which will never match sales. You are therefore condemned to a forecast reliability of 0%.

Does this prevent you on this SKU from providing your customers with excellent service while optimizing the use of your resources? No. Depending on the lead time of the item, a min/max with a max of 2 will do the trick.

The real question you need to ask yourself is: what replenishment process do I need to put in place to fulfill the orders on this item? Do I need to stock this item? How do I trigger its replenishment? Can I do it in delayed differentiation?

For such an item, do not waste the energy of your teams to develop an erroneous forecast: focus your efforts on implementing an agile supply chain operating model driven by actual orders.

Forecasting, what for?

The purpose of information is to help make decisions.

Forecasts are useful to several functions in the company, to enable them to make decisions.

The management team needs forecasting scenarios to envision possible futures for the company, and to anticipate the adaptation of resources and strategic initiatives. We are at the heart of the S&OP process, and we need views aggregated by commercial and industrial families, with alternative scenarios and identification of major events.

Forecasts are also very useful for sales and marketing teams. They enable them to understand trends, correlate promotional actions and volumes, and fuel the sales dynamic. To do this, it is relevant to work by major customer, by market, product line, geography. What prevails is the collaborative process and the capture of relevant information on the life of the markets, not statistical algorithms.

But beware: to be successful, a sales force must be optimistic! New product launches are going to walk on fire, this promotion is going to leave competitors behind – it is humane, and healthy to motivate a sales force. Are you sure you want to align your capacity and inventory with this optimism?

For the planners of a Demand Driven operating model, forecasts are useful to decide in time on adaptations of the operating model: shift pattern, inventory pre build ahead of a promotion or supplier shut down, etc. They can be used for the dynamic adjustment of stock buffers. For some products, adjusting buffers based on a recent consumption history works very well, in other cases, particularly on products subject to promotions, the forecast must be used to adjust buffers. Very often a buffer sizing mechanism combining 50% recent history and 50% forecast gives good results.

Three different audiences with distinct needs, which put into perspective the key elements of a relevant supply chain forecasting process:

- Be able to easily aggregate views by families / groupings according to several dimensions. An aggregated forecast is more reliable than a detailed forecast, and decision making is done at aggregate levels.

- Being able to generate scenarios – optimistic, pessimistic, what if we win this tender?

- Know how to capture information about significant market events.

- To be able to generate dynamic stock buffer forecasts, only for strategic items that deserve it.

Forecasts are wrong, so what?

Certainly, the forecasts are wrong. However, we need a fair effort of anticipation. Even at the heart of a Kanban loop there is a “takt time” – which is nothing more than a forecast.

Let us go back to the basics of our forecasting needs. You are not interested in forecasting! You just want to be able to respond to a customer order at short notice and profitably.

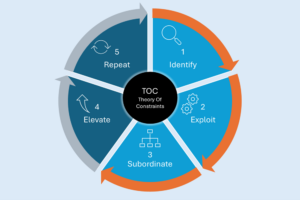

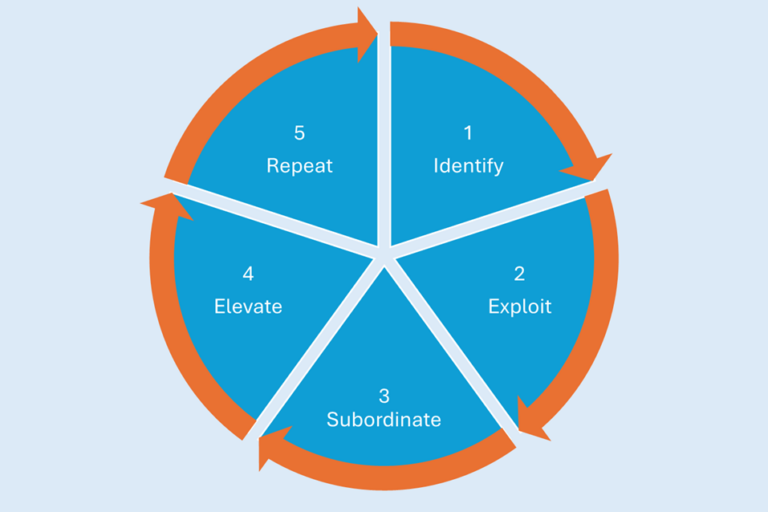

To do this you need to constantly adapt, to have the right resources in the right place at the right time. The question is to replenish in the right way, not to forecast – i.e. to establish a Demand Driven Operating Model.

To find out more about how our Demand Driven model can take forecasting into account, do not hesitate to request a demo or check out all of our Demand Driven model solutions!