The bullwhip effect: Supply Chain Practitioners know this phenomenon quite well – a slight change in demand downstream may create big swings upstream, and reversely small delays upstream may create a catastrophe to downstream supply chain partners.

This creates distortions and stress along the supply chain, resulting in shortages, overstocks and expediting costs.

If you are not a supply chain practitioner, you may have experienced the very same effect… it is called a traffic jam. Didn’t you get stuck in one of those severe slowdowns on the highway, without any identifiable cause?

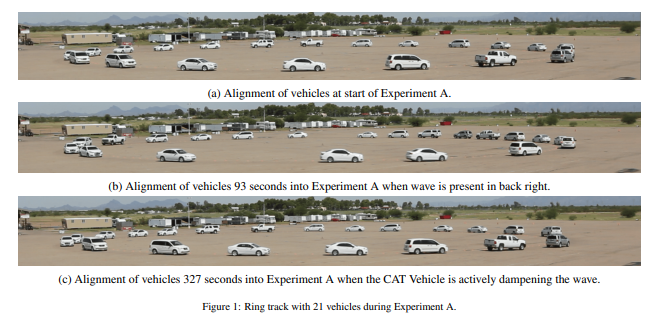

The experiment on the video below on a circular road shows how such phantom traffic jams appear.

In 2017, the MIT repeated the same experiment but inserted a single car equipped with an adaptive cruise control. It appeared that the insertion of this single buffer in the system was dampening the wave, and the traffic jam effectively disappeared. Although the video is no longer online, you can find more details about this experiment following the links below:

https://arxiv.org/pdf/1705.01693.pdf

How does this relate to Demand Driven practices?

Well, the stock and time buffers implemented in a Demand Driven Operating Model behave very much like an adaptive cruise control does. When the buffer gets too empty or too full, actions are taken to seamlessly adjust the pace upstream.

You do not need to place buffers everywhere; you insert them only in select positions to dampen variability.

And consequently, there is way less stress for the drivers.

Give it a try… (trying the adaptive cruise control I mean)