When you mention a Kanban board to the younger generation, they immediately think of a visualization board for to-do / in-progress / completed tasks – and the Agile project management method. Just do a web search, and that’s what you’ll find…

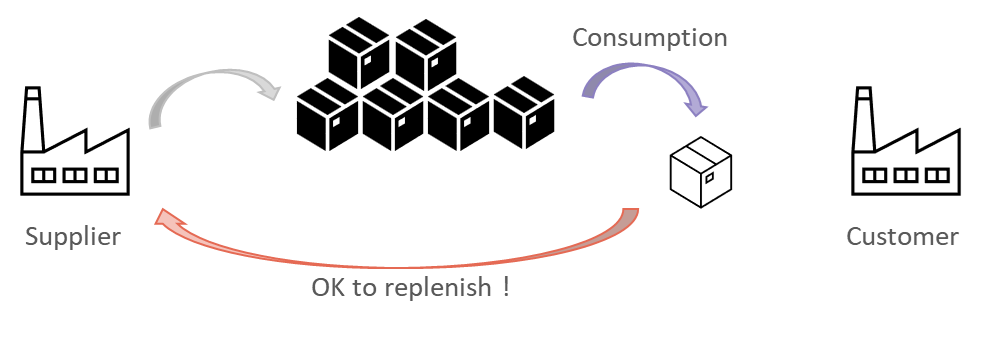

For veterans like me, a Kanban loop is a replenishment management method – when the downstream item/customer consumes, this consumption generates a signal to the upstream process/supplier, to authorize replenishment.

Something like this:

This mode of operation offers several benefits:

– The flow is driven by actual consumption downstream. When there’s no need, there’s no need to build up stock. If we consume faster, we call for more supplies, in real time. It’s common sense.

– We size a loop (number of bins/cards / total quantity). Current stock + on order can never exceed this loop.

– The system is generally very visual, with display boards.

Invented in Japan in the middle of the 20th century, the kanban method has been enriched as it has been deployed, notably in the automotive industry, with accumulation boards to create batches, Heijunka mechanisms to smooth out the load, launching boards to manage sequences, etc. Originally based on physical boards and cards, electronic versions were developed to facilitate loop management and meet dematerialization needs.

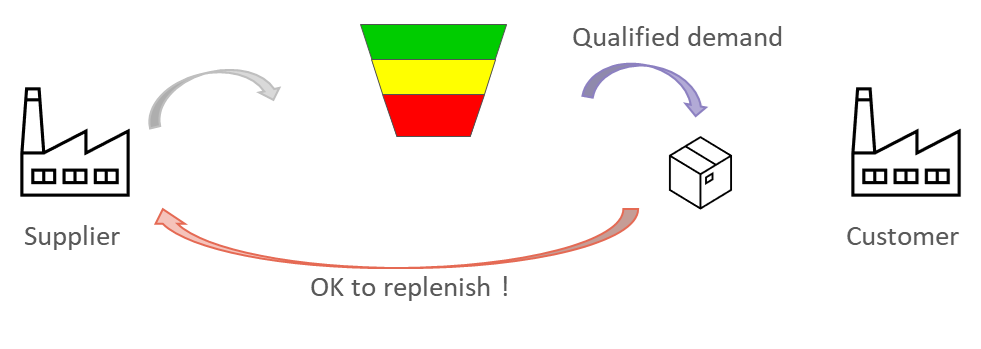

A DDMRP buffer-driven replenishment loop looks like this:

Sounds similar, doesn’t it?

The basic operating principles are the same: pull flow, driven by actual downstream demand. Work-in-process is sized by the loop, and the supplier cannot push more than the signal triggered by actual demand.

Is this what it’s all about? Are we getting excited about the rebranding of a Japanese concept from 1950? Just enough to get the younger generation of digital natives interested in pull flow?…

Not quite. We all know that, after decades of existence, pull flow is still in the minority when it comes to managing supply chains. MRP – whose weaknesses have been known and recognized since at least the 90s – is still predominant.

A DDMRP stock buffer promises that it responds better to variability than a kanban loop. It’s a fact: a Kanban loop responds very well when there’s a significant, stable flow. When demand is more variable – seasonal, event-driven, erratic – it’s complicated.

A DDMRP buffer responds much better in a variable environment, as demonstrated by deployments over more than a decade, as well as by academic research from 2018.

What are the objective differences in the DDMRP loop mechanism?

Dynamic loop

A DDMRP buffer is dynamic: the size of the loop adapts according to changes in demand – historical or forecast. No more tedious kanban adjustments.

This feature may exist in a kanban model, especially an electronic kanban – but it’s particularly well-equipped in a DDMRP loop.

Qualified demand

The flow equation considers a portion of the demand, whereas the kanban only reacts when consumption has been achieved. Can you see the difference between the two diagrams above? In one case, we only look at consumption, in the other at “qualified demand”. This makes it easier to react to variable demand.

Qualified demand takes three components into account:

– Past due demand/backorders. A kanban that only reacts to consumption ignores these backorders and will only authorize an increase in supply when the downstream operation begins to catch up. At most, if the kanban loop is empty, the total quantity of the kanban loop will be on order on the supplier side. In a DDMRP loop, the flow equation may be negative due to accumulated delays, so more orders are placed.

– Today’s demand. Compared to a Kanban, we only anticipate what we’ll need to ship today – which in practice anticipates a consumption event deemed certain by a few hours.

– Demand peaks within a defined future horizon. To manage this in a conventional kanban, we need to detect that we’re going to have exceptional demand and inject into the loop several “single-use” cards to cover this demand with a spot supply. This mechanism is systematic/industrialized in a DDMRP buffer.

Taking a portion of the demand into account allows the replenishment quantity to exceed the buffer size. Some might consider this laxer than a kanban, which systematically constrains the order quantity to the loop size.

However, it requires rigorous management, as the “qualified demand” signal must be clean.

For example, if you apply a DDMRP loop to child items in a factory, it’s important that the production orders for the parent items are positioned in the future, and that they reflect what you know you will be able to manufacture. You are not going to manufacture anything last week…

Execution: FIFO or not

In the execution phase, the priority of supply orders in a kanban loop is generally treated on a FIFO basis. This is not the case for a DDMRP loop, where priorities are continuously adjusted according to the health of the downstream stock. Particularly in the case of longer loops, this difference is essential.

Hybrid push/pull loop

A DDMRP loop easily integrates a chain of dependencies in push mode (I manufacture a sub-assembly in flow with a final assembly) – with the decoupled lead-time and decoupled BOM explosion calculation mechanisms it is easy to manage these very frequent combinations in industry. Organizing this type of hybrid loop with a conventional kanban is possible, but in my experience far more complex to design and orchestrate.

Several other considerations can be added to this comparison: standardized vs. proprietary electronic kanban system, historical performance analysis dashboards, simulation and projection capability, relative priorities, etc. A DDMRP loop brings Kanban up to date, facilitates end-to-end deployment, and facilitates the adoption of pull flow by most companies!