In the early 90s, I was in charge of IT at a Philips industrial site and had the good fortune of being in charge of our IBM 38 replacement with the brand-new AS/400 implementation, which had come out in 1988. This was a huge step forward, including for the planet (which wasn’t our concern at the time), as the IBM 38 required two air conditioners in our computer room, which we were able to switch off.

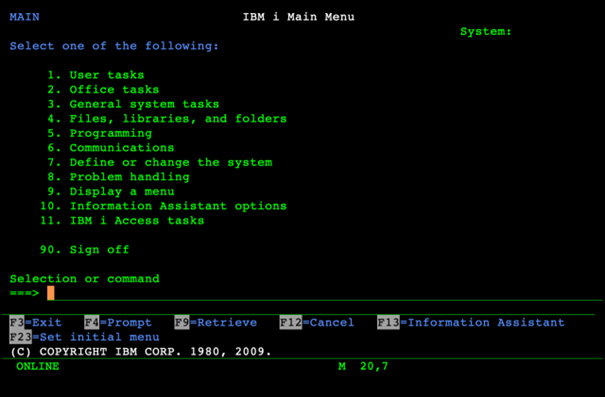

It was a different era, before Windows and the Internet. Screens displayed only text, with a choice of green or amber color. However, there was a robust database system, using SQL for queries; it was structured and powerful.

In 2024, it’s curious to find many companies running on an legacy ERP system whose core dates back to that era… They were called Mapics, MFG Pro, Baan, and Movex – and are still at the heart of plant management, even in large corporations. Admittedly, they have often been renamed and dressed up with graphic overlays, but at heart, it’s the same engine – and it’s not uncommon to nostalgically rediscover those original text screens…

We live in an age of constantly evolving web and mobile applications, and our daily lives as digital citizens have become accustomed to this. Our cell phones, tablets, and personal PCs live at this pace – an application that is more than two years old is showing signs of obsolescence.

Curiously, when it comes to managing their supply chains and factories, most companies remain entangled in old-fashioned technology and are reluctant to touch the spaghetti dish that has been built up over time around the original ERP. Fortunately – and unfortunately – Excel has enabled users to make up for a few shortcomings… but added a healthy dose of fragility.

People make fun of AS/400 text screens, but let’s not forget that most SAP sites run on ECC6, the 2006 version of SAP R/3 from 1992… No better!

Why is it taking so long when technology has evolved so much in recent decades?

The answer is undoubtedly multifaceted. Changing ERP, or upgrading to a new version, is a major and very costly undertaking. So, we delay, we freeze, we wait, we hesitate until the day comes when we have to go ahead.

The other aspect is that ERP vendors themselves have not been prolific in supply chain innovations. Let’s not forget that the primary motivation for ERPs is on the financial side.

This inertia has contributed to the boom in innovative digital solutions over the past years. Long reluctant to move away from the “all-ERP” approach, IT departments have come to understand that the added value of ERP lies in the transactional aspect, not in decision-making.

The “all-erp” approach leads to “all-Excel”.

By transferring the decision-making layer to modern, scalable applications such as Intuiflow, we greatly reduce the intrinsic inertia of the ERP ecosystem, structure processes scattered across Excel, and make life easier for users, with intuitive interfaces and exception-based wizards.

The proponents of “all-erp” are not giving up. I’ve heard it said several times recently: “We’re going to switch to [S4/Hana, D365 F&O, Infor LN, etc.] and the new version does it all, we won’t need any additional applications to support S&OP, DDMRP, scheduling, BI, etc.”.

Ahah. Let’s talk about it again in a while.