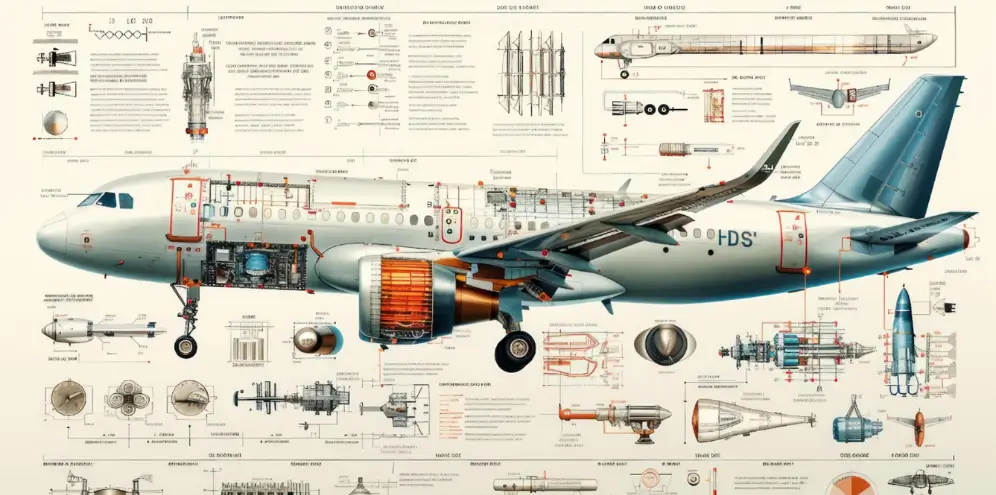

The challenges of managing the Aero and Defense Supply Chain

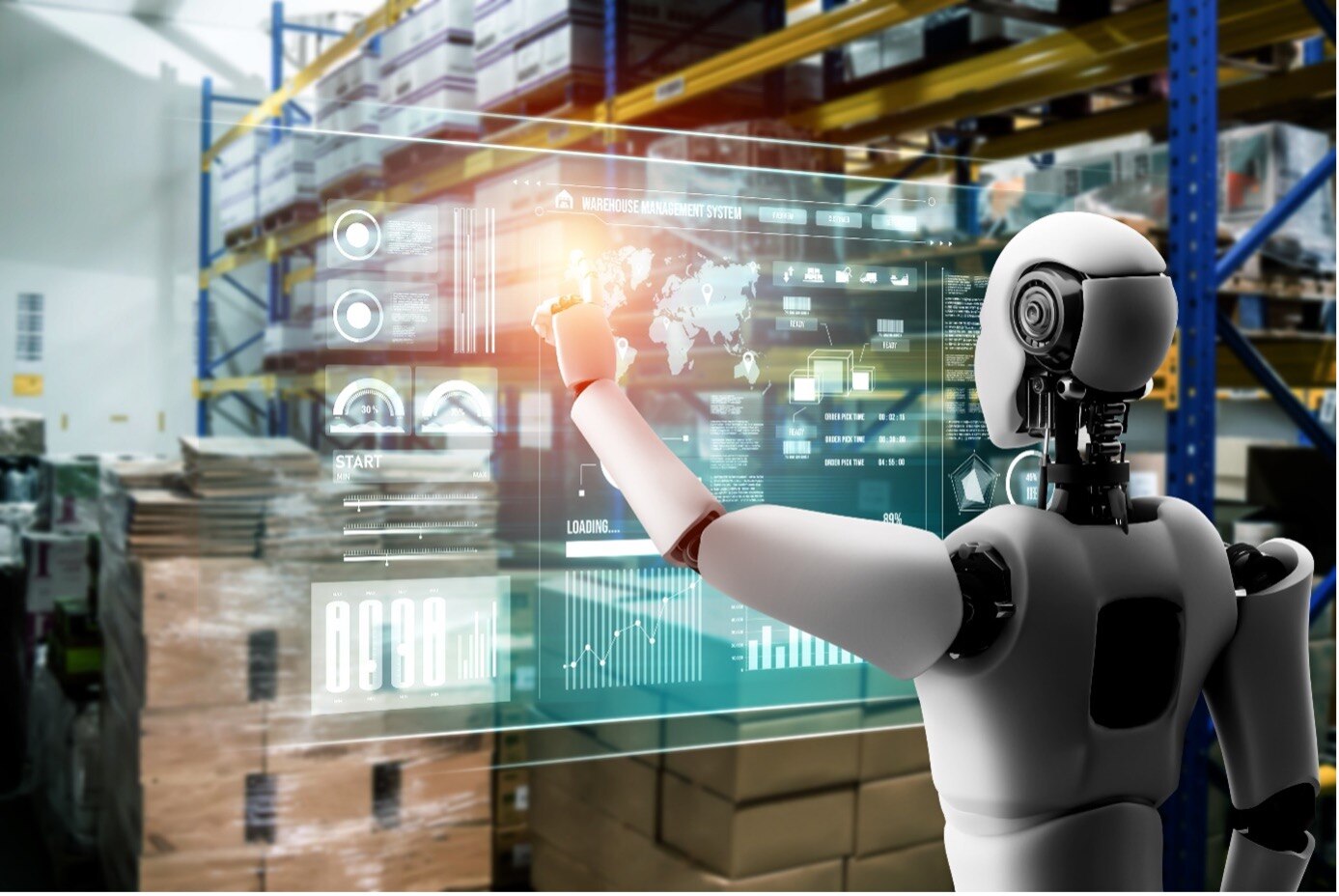

Faced with a changing geopolitical environment and capability challenges, the aerospace and defense supply chain need to reinvent itself. This industry has traditionally adopted classic MRP planning methods and has sometimes injected a little Lean at production cell level, but has not really designed a steering model adapted to its challenges. The result is that, … Read more