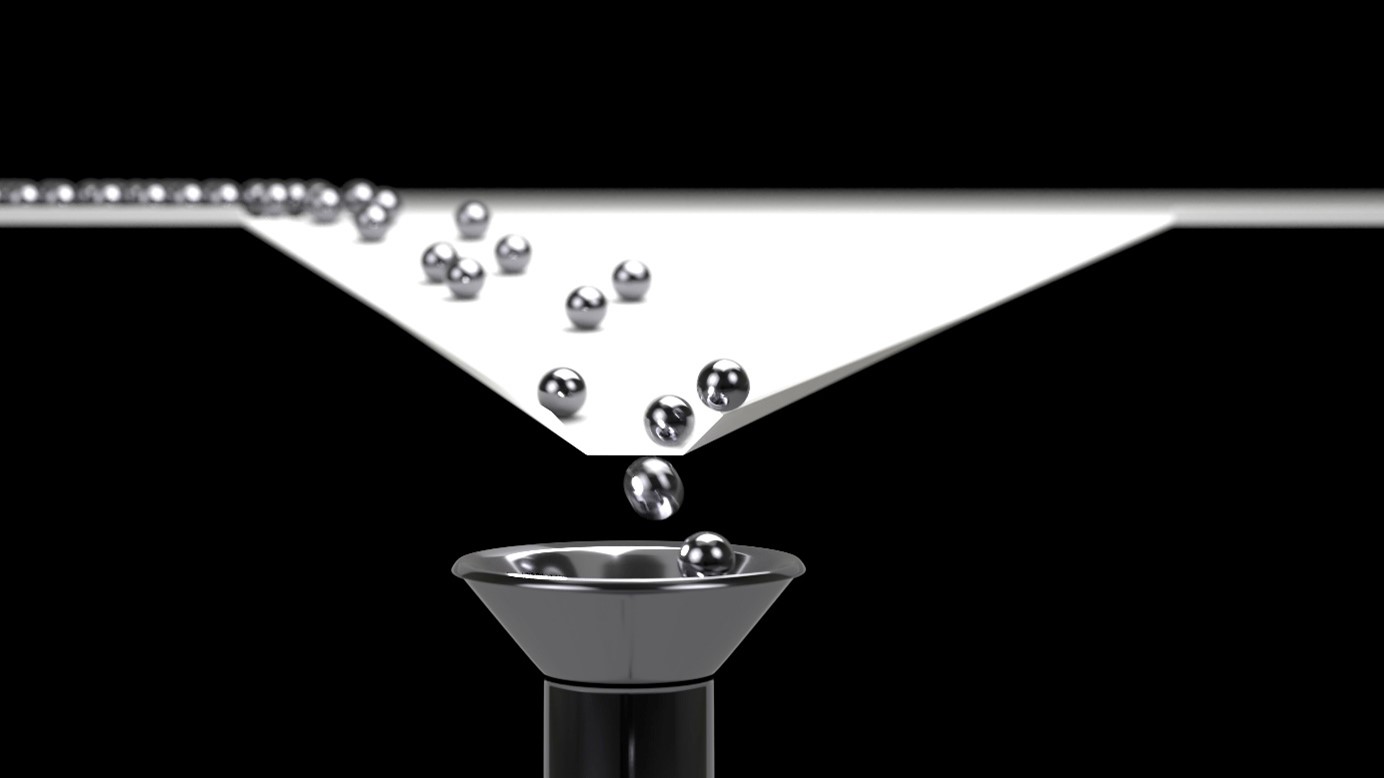

Understanding Demand-Based Forecasts

To size our stocks and replenish our products, we need to use a demand assumption. In a Demand Driven approach, the supply chain is scheduled based on real consumption, but for consumption to occur, it must have been initiated by available products, supplied based on a demand hypothesis.